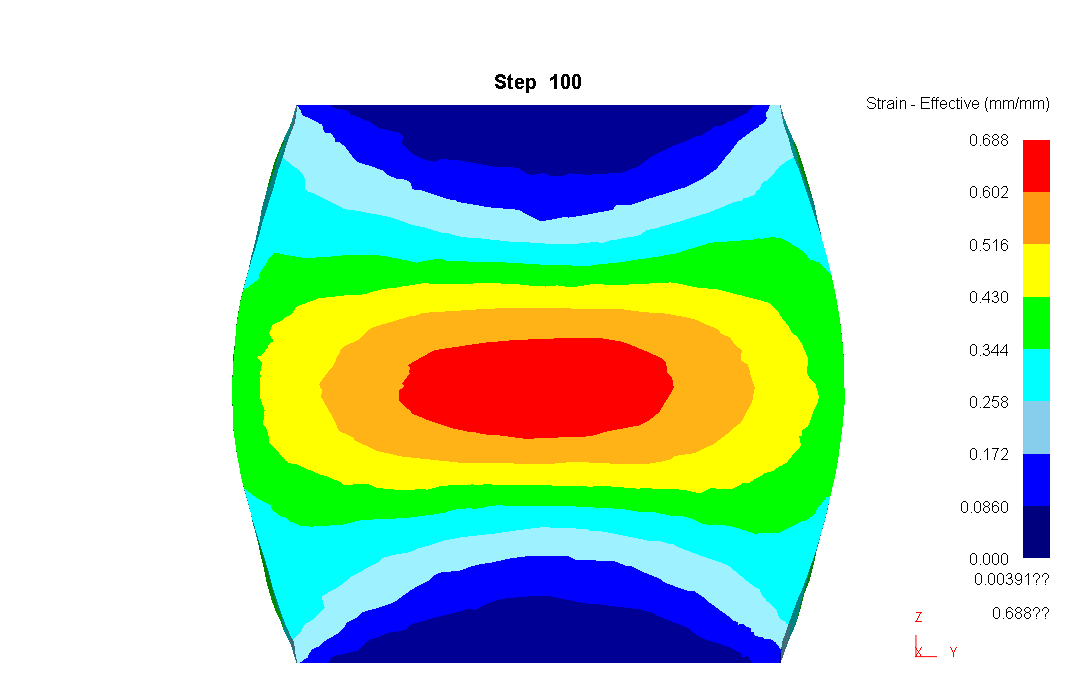

通过Deform-3D三维几何建模软件对烧结纯钼的多向锻造过程进行数值模拟,采用Pro-Engineering三维几何建模软件,建立模型图。选择Langrangian增量形式计算锻造过程中的塑性变形。通过共轭梯度法计算单步,计算步之间采用直接迭代。锻造砧与锻件接触,锻造砧温度300 ℃,界面热传系数为5 N/(sec·mm·℃),环境温度为20 ℃,热对流系数为0.02 N/(sec·mm ℃)。设置不同相互间的库伦摩擦系数、锻造温度、锻造速率、锻造变形量等参数,探究最优选的锻造方案。采用真应变计算公式,通过锻件的尺寸,在软件中设置模具压下量的方法,获得单次压下量的等效应变图;通过软件前处理模块对锻件温度的设置,在后处理模块中,通过选择不同切分位置,获得不同温度下锻造后锻件的等效应变图及单向温度流线图;通过软件设置模具下压速率,在后处理模块中获得后期金属流动速度分布图。

The multi-directional forging process of sintered pure molybdenum was numerically simulated by Deform-3D three-dimensional geometric modeling software, and the model diagram was established using Pro-Engineering three-dimensional geometric modeling software. The Langrangian incremental form is selected to calculate the plastic deformation during the forging process. A single step is calculated by the conjugate gradient method, and direct iteration is used between calculation steps. The forging anvil is in contact with the forging, the temperature of the forging anvil is 300 ℃, the interface heat transfer coefficient is 5 N/(sec·mm·℃), the ambient temperature is 20 ℃, and the heat convection coefficient is 0.02 N/(sec·mm ℃). Set parameters such as Coulomb friction coefficient, forging temperature, forging rate, and forging deformation between different mutuals, and explore the most optimal forging plan. Using the true strain calculation formula, through the size of the forging, the method of setting the die reduction in the software to obtain the equivalent strain diagram of the single reduction; the setting of the temperature of the forging through the pre-processing module of the software is in the post-processing module , By selecting different cutting positions, obtain the equivalent strain diagram and unidirectional temperature streamline diagram of the forging after forging at different temperatures; set the die pressing rate through the software, and obtain the later metal flow velocity distribution diagram in the post-processing module.