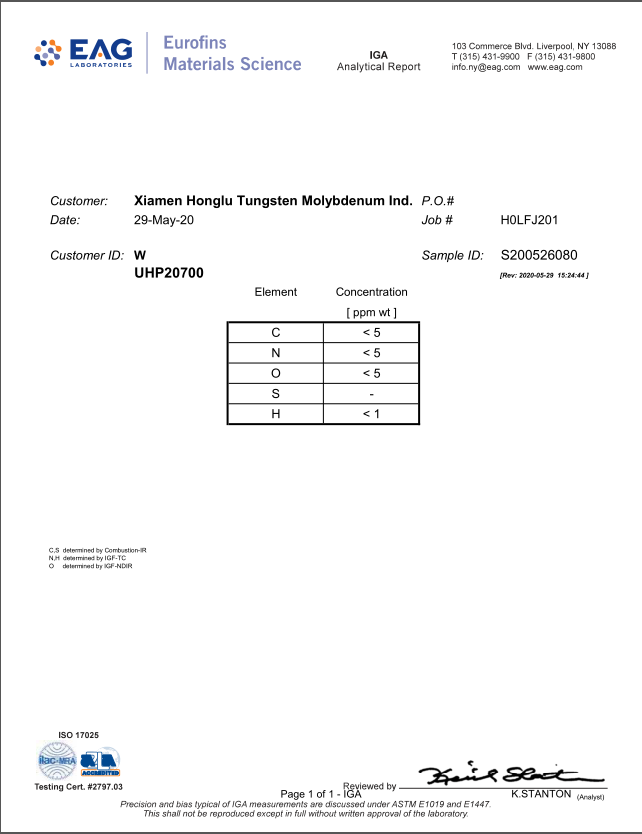

以高纯钨粉为原料,通过等静压和烧结成型,烧结温度2300℃,然后再在轧机上进行轧制,制备出超高纯钨板。钨板制备完成后,线切割取样10*10*T(避开边缘20mm),然后六面磨光,超声波清洗烘干后,双层真空包装,然后寄给相应的第三方检测机构进行氧含量的检测。

Ultra-high purity tungsten plate was prepared by isostatic pressing and sintering with high purity tungsten powder at 2300℃ and then rolling on a rolling mill. After the tungsten plate is prepared, sample 10*10*T by wire cutting (avoid edge 20mm), then six sides are polished, ultrasonic cleaning and drying, double vacuum packaging, and then sent to the corresponding third-party testing institutions for oxygen content detection.