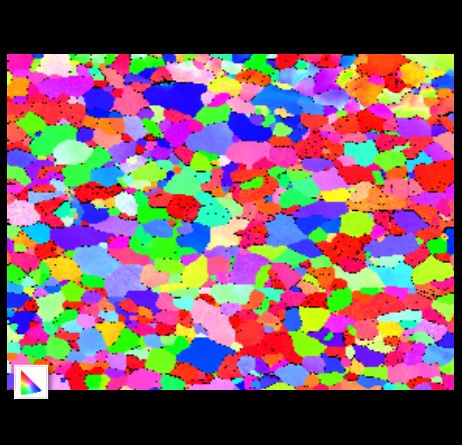

采用纯度为99.97%的高纯钼粉为原料,制备出相同规格的烧结钼板坯,分别在1200℃、1300℃、1400℃、1500℃温度下加热2小时,随后通过相同的一火多道次热轧工艺制备出热轧钼板,热轧钼板在1200℃/1h条件下进行再结晶退火处理,对不同变形量热轧钼板退火前后的晶粒组织和织构进行EBSD分析。EBSD采集方案:首先对样品表面进行机械研磨和抛光,然后在25%高氯酸和75%的酒精混合溶液中,以10±2 V的电压和45±5 A的电流进行电解抛光,持续时间为120-300 s。通过EDAX配置的电子背散射衍射(EBSD)进行测量,扫描步长设为0.05°,扫描时间为30 min/样。

Using high-purity molybdenum powder with a purity of 99.97% as raw material, sintered molybdenum slabs of the same specifications were prepared, heated at 1200°C, 1300°C, 1400°C, and 1500°C for 2 hours, and then passed through the same fire and multiple passes. The hot-rolled molybdenum sheet was prepared by the secondary hot rolling process, and the hot-rolled molybdenum sheet was subjected to recrystallization annealing treatment at 1200℃/1h. The grain structure and texture of the hot-rolled molybdenum sheet with different deformations before and after annealing were analyzed by EBSD. EBSD collection scheme: first mechanically grinding and polishing the surface of the sample, and then electropolishing in a 25% perchloric acid and 75% alcohol mixed solution with a voltage of 10 ± 2 V and a current of 45 ± 5 A, duration Is 120-300 s. The measurement is carried out by electron backscatter diffraction (EBSD) configured by EDAX, the scanning step is set to 0.05°, and the scanning time is 30 min/sample.