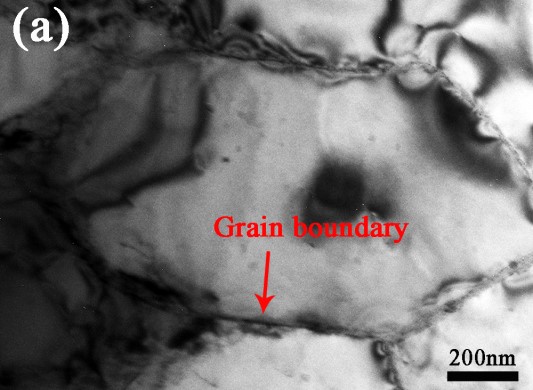

采用金堆城钼业股份有限公司提供的常规粒度(纯度大于99.95%,直径约3.5 μm)纯钼粉,经还原后在YT79-500液压机对钼粉进行180 MPa冷等静压成坯,随后在中频氢气气氛烧结炉内进行固相分段式烧结,烧结温度为1880°C。将制得的烧结坯经线切割,获得尺寸为 8×12 mm的圆柱形试样,不少于16个。每个圆柱形试样均经过端面打磨以保证良好接触摩擦条件。经加热炉加热后分别在四个不同温度(1150 °C,1200 °C,1250 °C,1300 °C)和四个不同应变速率(0.01 s-1,0.1 s-1,1 s-1,10 s-1)组合条件下进行单道次热压缩测试,应变量均为60%,共计16组。使用不同粒度砂纸将变形后的试样打磨至20 μm。然后在温度为-30 °C,电压为30 V,电流为50 A,电解液为6%高氯酸和酒精混合溶液的双喷电解减薄机上对样品进行双喷减薄,处理好的样品在下透射电子显微镜进行观察。

The pure molybdenum powder with conventional particle size (purity greater than 99.95%, diameter about 3.5 μm) provided by Jinduicheng Molybdenum Industry Co., Ltd. was used to perform 180 MPa cold isostatic pressing of the molybdenum powder into a compact after reduction in a YT79-500 hydraulic press, and then The solid phase sintering is carried out in an intermediate frequency hydrogen atmosphere sintering furnace, and the sintering temperature is 1880°C. The prepared sintered billet was cut by wire to obtain no less than 16 cylindrical specimens with a size of 8×12 mm. Each cylindrical specimen is polished on the end face to ensure good contact and friction conditions. After being heated by a heating furnace, it is heated at four different temperatures (1150 °C, 1200 °C, 1250 °C, 1300 °C) and four different strain rates (0.01 s-1, 0.1 s-1, 1 s-1, 10 s-1) A single-pass thermal compression test is carried out under combined conditions, and the strain amount is 60%, a total of 16 groups. Grind the deformed sample to 20 μm with sandpaper of different grain sizes. Then, the sample is thinned by double spraying on a double spray electrolytic thinning machine with a temperature of -30 °C, a voltage of 30 V, a current of 50 A, and a mixed solution of 6% perchloric acid and alcohol. The processed sample Observe under the transmission electron microscope.