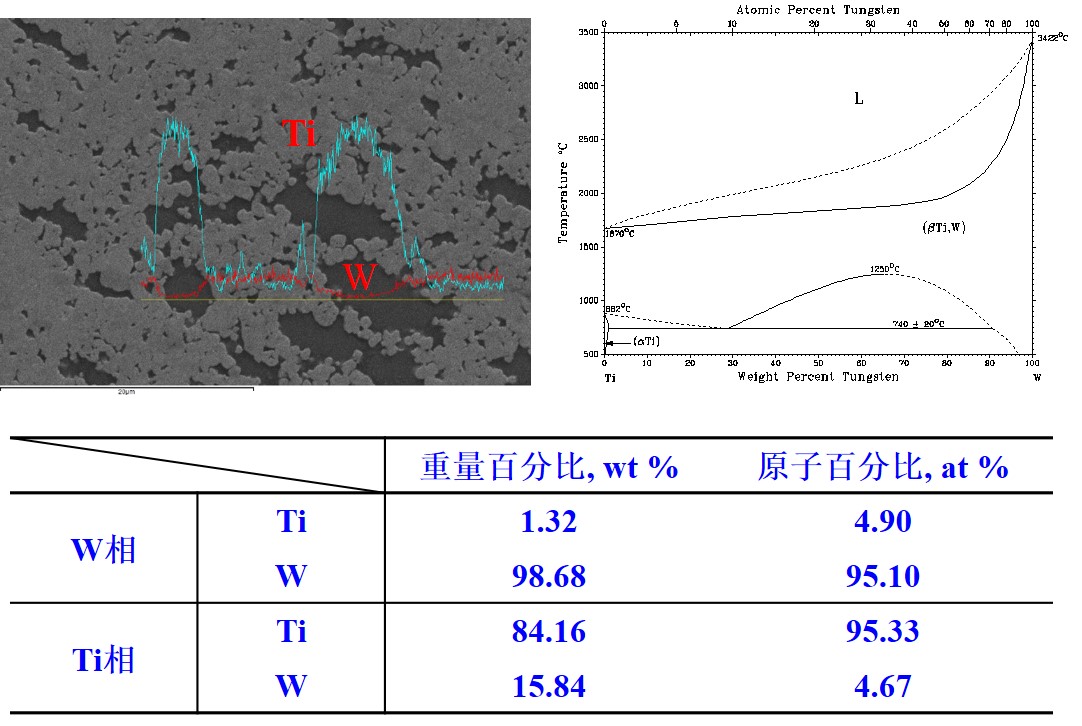

将200 nm、1.0 μm和10 μm三种粒度的高纯钨粉末,分别混合10%的1.0微米纯钛粉末,借助放电等离子烧结(SPS)炉进行高温压力烧结,制备出尺寸为φ60×10mm的W-Ti10合金样品。烧结气氛为真空,烧结压力50 MPa,烧结温度为1400℃,保温时间为10分钟。从烧结样品的心部进行电火花线切割取样,借助金相抛光机进行金相制样和化学腐蚀。在扫描电镜下观察样品的显微组织和物相构成,并拍摄SEM照片。并借助SEM扫描电镜的能谱功能,鉴定显微组织中物相组成,确定化学元素构成。

The high-purity tungsten powder with three particle sizes of 200 nm, 1.0 μm and 10 μm was mixed with 10% 1.0 micron pure titanium powder respectively, and the spark plasma sintering (SPS) furnace was used for high-temperature pressure sintering to prepare a size of φ60×10mm. W-Ti10 alloy sample. The sintering atmosphere is vacuum, the sintering pressure is 50 MPa, the sintering temperature is 1400°C, and the holding time is 10 minutes. Wire EDM samples were taken from the core of the sintered sample, and metallographic sample preparation and chemical corrosion were performed with the help of a metallographic polishing machine. Observe the microstructure and phase composition of the sample under the scanning electron microscope, and take SEM pictures. And with the help of the energy spectrum function of the SEM scanning electron microscope, the phase composition in the microstructure is identified, and the chemical element composition is determined.