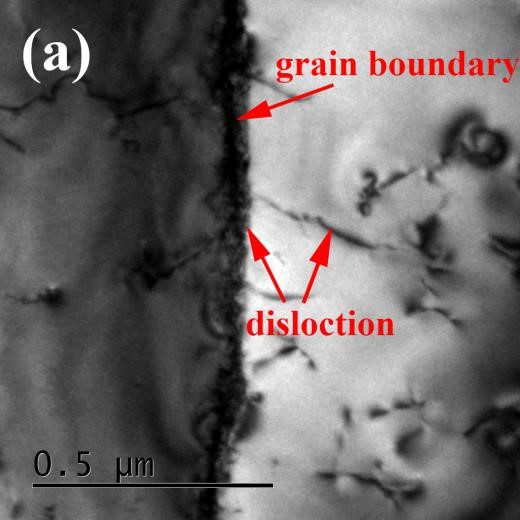

利用粉末冶金法制得了板型规整的纯钼烧结坯,在Gleeble-1500型热模拟实验机上对纯钼板坯进行热压缩变形实验,变形温度为1100°C~1300 °C、变形速率为0.01~10 s-1、真应变为0.3~0.6。使用不同粒度砂纸将变形后的试样打磨至20 μm。然后在温度为-30 °C,电压为30 V,电流为50 A,电解液为6%高氯酸和酒精混合溶液的双喷电解减薄机上对样品进行双喷减薄,处理好的样品在下透射电子显微镜进行观察。

A pure molybdenum sintered compact with a regular plate shape was prepared by powder metallurgy. The pure molybdenum slab was subjected to a thermal compression deformation experiment on the Gleeble-1500 thermal simulation test machine. The deformation temperature was 1100°C~1300°C, and the deformation rate was 0.01~ 10 s-1, the true strain is 0.3 to 0.6. Grind the deformed sample to 20 μm with sandpaper of different grain sizes. Then, the sample is thinned by double spraying on a double spray electrolytic thinning machine with a temperature of -30 °C, a voltage of 30 V, a current of 50 A, and a mixed solution of 6% perchloric acid and alcohol. The processed sample Observe under the transmission electron microscope.