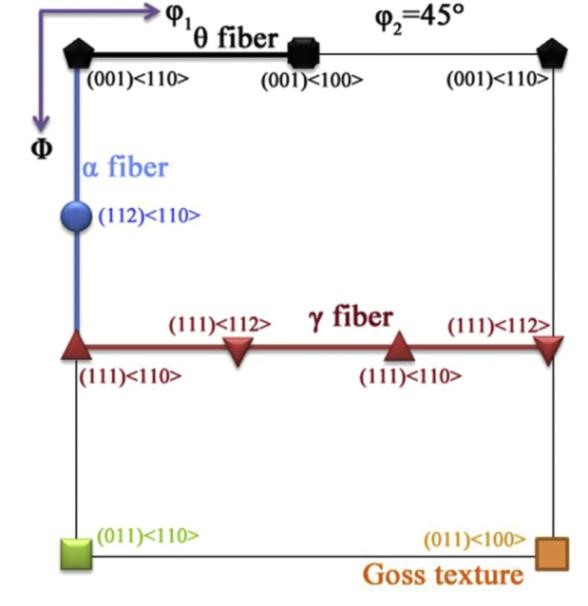

利用粉末冶金法制得了板型规整的纯钼烧结坯,在Gleeble-1500型热模拟实验机上对纯钼板坯进行热压缩变形实验,变形温度为1100°C~1300 °C、变形速率为0.01~10 s-1、真应变为0.3~0.6。每个形变在状态的样品在X射线衍射仪下测得宏观织构。测试之前样品表面进行机械抛光,通过测量样品中三个不完全极坐标{110},{200},{211}来检测样品宏观织构,将不同变形条件的样品用XRD测量其织构,再用MATLAB软件分析处理数据,得到不同变形条件织构的极图(PF)、反极图(IPF)与三维取向分布函数图(ODF)。

A pure molybdenum sintered compact with a regular plate shape was prepared by powder metallurgy. The pure molybdenum slab was subjected to a thermal compression deformation experiment on the Gleeble-1500 thermal simulation test machine. The deformation temperature was 1100°C~1300°C, and the deformation rate was 0.01~ 10 s-1, the true strain is 0.3 to 0.6. The macro-texture of each deformed sample is measured under the X-ray diffractometer. Before the test, the surface of the sample is mechanically polished, and the macro-texture of the sample is measured by measuring the three incomplete polar coordinates {110}, {200}, {211} in the sample. The texture of the sample with different deformation conditions is measured by XRD, and then The data was analyzed and processed with MATLAB software, and the pole figure (PF), the inverse pole figure (IPF) and the three-dimensional orientation distribution function diagram (ODF) of the texture under different deformation conditions were obtained.