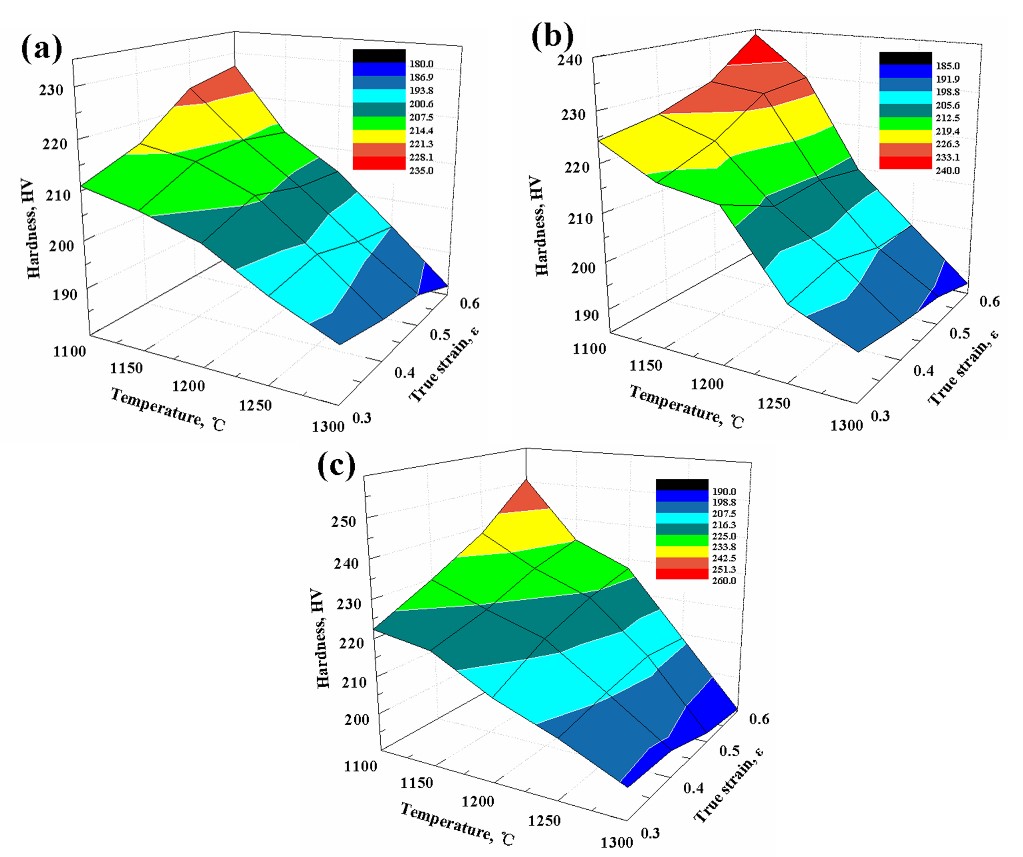

采用粉末冶金法制备了具有规则板状的纯钼烧结体。 纯钼板坯在Gleeble-1500热模拟试验机上进行热压缩变形实验。 变形温度为1100℃~1300℃,变形速率为0.01~10 s-1,真应变为0.3~0.6。 试样抛光后,调整试验载荷为200 g,保压时间为10 s,对每个试样的中心进行10次显微硬度试验,取硬度平均值,分析试样的硬度变化规律。 不同的变形条件。

A pure molybdenum sintered compact with a regular plate shape was prepared by powder metallurgy. The pure molybdenum slab was subjected to a thermal compression deformation experiment on the Gleeble-1500 thermal simulation test machine. The deformation temperature was 1100°C~1300°C, and the deformation rate was 0.01~ 10 s-1, the true strain is 0.3 to 0.6. After the samples are polished, the test load is adjusted to 200 g, the pressure holding time is 10 s, and 10 microhardness tests are performed on the center of each sample to obtain the average value of the hardness and analyze the hardness change law of different deformation conditions.