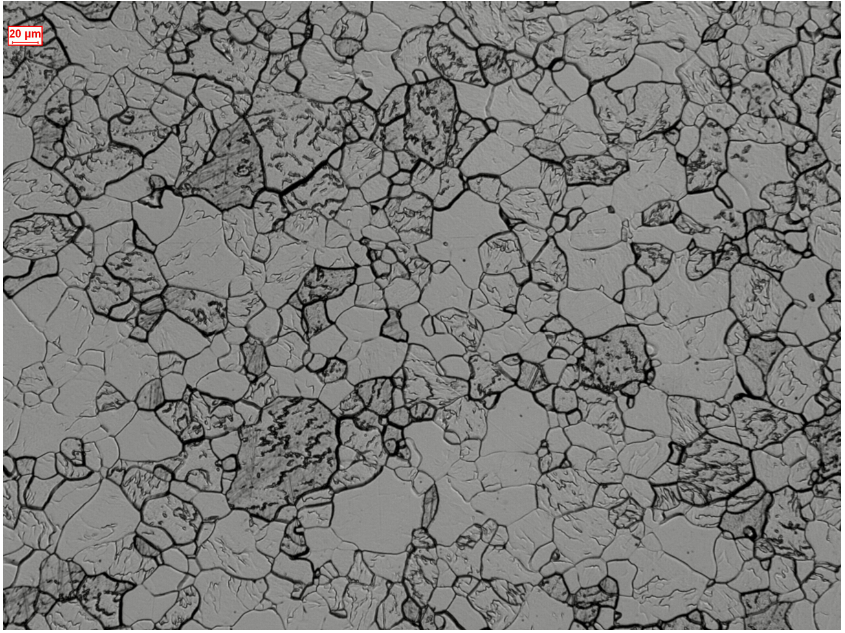

采用纯度为99.95%的钼粉分别压制、烧结出钼板坯,烧结钼板坯经1400℃加热后,分别采用一火多道次和两火多道次的工艺轧制到同样的厚度。将热轧后的钼板在1200℃退火1h后,对其表面和纵截面的金相组织进行观察。金相组织采集方案:试样经过机械磨削和抛光成平整、光亮、无磨痕或抛光划痕的镜面,采用10-20%的氢氧化钠+铁氰化钾混合液(氢氧化钠与铁氰化钾质量比为1:1)对样品进行腐蚀,腐蚀后的样品在金相显微镜下放大100×或200×进行金相组织观察。

Molybdenum slabs are respectively pressed and sintered with molybdenum powder with a purity of 99.95%. After sintered molybdenum slabs are heated at 1400°C, they are rolled to the same thickness by a process of one fire and multiple passes and two fires and multiple passes. After the hot-rolled molybdenum sheet was annealed at 1200°C for 1 hour, the metallographic structure of the surface and longitudinal section was observed. Metallographic structure collection scheme: The sample is mechanically ground and polished into a smooth, bright, and non-abrasive or polished mirror surface, using a 10-20% sodium hydroxide + potassium ferricyanide mixture (sodium hydroxide and potassium ferricyanide) The mass ratio of potassium ferricyanide is 1:1) The sample is corroded, and the corroded sample is magnified 100× or 200× under a metallurgical microscope to observe the metallographic structure.