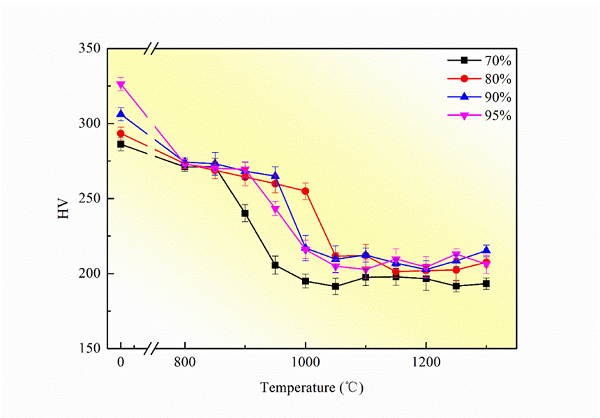

利用粉末冶金法制得了板型规整的纯钼烧结坯,在1350℃对烧结坯进行开坯热轧。制备好的热轧纯钼板材试样在800–1300◦C退火。线切割退火样品,进行打磨抛光后,在401MVD型数显显微维氏硬度计上测试显微硬度,试验载荷为200 g,保压时间10 s,得到不同变形量板材的硬度变化规律。

A pure molybdenum sintered compact with a regular plate shape was prepared by powder metallurgy, and the sintered compact was hot rolled at 1350°C. The prepared hot-rolled pure molybdenum sheet samples were annealed at 800–1300°C. Wire-cut annealed samples, after grinding and polishing, hit the microhardness 20 times on the 401MVD digital micro Vickers hardness tester, the test load is 200 g, the pressure holding time is 10 s, and the data is recorded at the same time, and the average value is obtained As well as the error, the hardness change law of the plates with different deformation amounts is obtained.