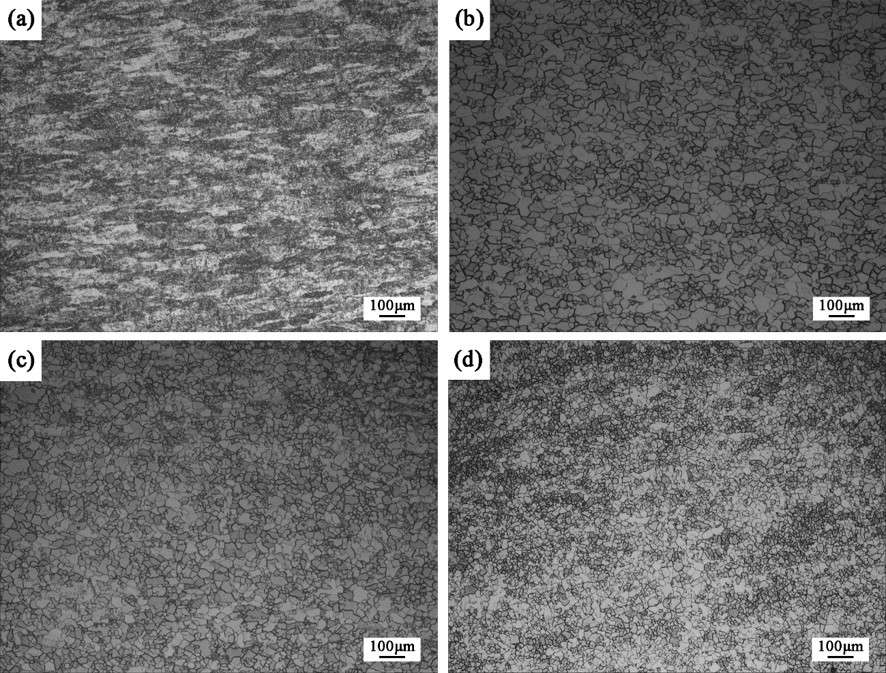

利用粉末冶金法制得了板型规整的纯钼烧结坯,在轧制过程中通过热轧、温轧、冷轧、热处理、碱洗工序制备不同变形量的轧制板材。在1350℃对烧结坯进行开坯,开坯变形量为30%,热轧每道次压下量控制在20%~30%以内,温轧每道次压下量控制在10~20%以内,冷轧每道次压下量控制在10%以下。制备好后的纯钼板材试样采用光学显微镜(OM)、扫描电子显微镜(SEM)和透射电子显微镜(TEM)对样品的组织、断口和位错组态进行表征。金相观察使用线切割将轧制板材尺寸切为沿轧制方向长度为10 mm,宽度为5 mm,然后使用金相镶样机进行镶样,采用不同粒度的砂纸进行打磨,最后用抛光机进行抛光,使用腐蚀剂(铁氰化钾:氢氧化钠:水为1:1:10)在试样表面擦拭40 s左右进行腐蚀,腐蚀之后用酒精擦洗再用吹风机吹干,采用光学显微镜和扫描电镜下观察组织形貌。TEM:使用线切割加工得到长10 mm×宽5 mm的板材,使用不同粒度砂纸将试样打磨至20 μm。然后在温度为-30 °C电压为30 V,电流为50 A,电解液为6 %高氯酸酒精混合溶液的双喷电解减薄机上对样品进行双喷减薄。处理好的样品在透射电镜下进行观察。EBSD:原始尺寸长10 mm×宽5 mm,将样品在电压为20 V,温度为20 °C,电解液为H2SO4:CH3OH为12: 88的混合溶液电解抛光,处理好的样品在场发射扫描电镜JSM-6700F下进行观察分析。

A pure molybdenum sintered billet with a regular plate shape is prepared by powder metallurgy, and rolled plates with different deformations are prepared through hot rolling, warm rolling, cold rolling, heat treatment, and alkaline washing during the rolling process. The sintered billet is opened at 1350℃, the billet deformation is 30%, the reduction of each pass of hot rolling is controlled within 20%~30%, and the reduction of each pass of warm rolling is controlled within 10~20% , The reduction of each pass of cold rolling is controlled below 10%. The prepared pure molybdenum sheet samples were characterized by optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM) to characterize the structure, fracture and dislocation configuration of the sample. Metallographic observation uses wire cutting to cut the size of the rolled sheet to a length of 10 mm along the rolling direction and a width of 5 mm, and then use a metallographic mounting machine for mounting, using different grit sandpaper for sanding, and finally using a polishing machine Polishing, use corrosive (potassium ferricyanide: sodium hydroxide: water 1:1:10) to wipe the surface of the sample for about 40 seconds to corrode. After corrosion, scrub with alcohol and blow dry with a hair dryer, using optical microscope and scanning electron microscope Observe the morphology of the tissue. TEM: Use wire cutting to obtain a 10 mm long x 5 mm wide plate, and use different grit sandpaper to polish the sample to 20 μm. Then, the sample was thinned on a dual-jet electrolytic thinning machine with a temperature of -30 °C, a voltage of 30 V, a current of 50 A, and an electrolyte of 6% perchlorate-alcohol mixed solution. The processed sample was observed under the transmission electron microscope. EBSD: The original size is 10 mm long and 5 mm wide. The sample is electropolished at a voltage of 20 V, a temperature of 20 °C, and a mixed solution of H2SO4: CH3OH of 12: 88. The processed sample is subjected to a field emission scanning electron microscope. Observe and analyze under JSM-6700F.