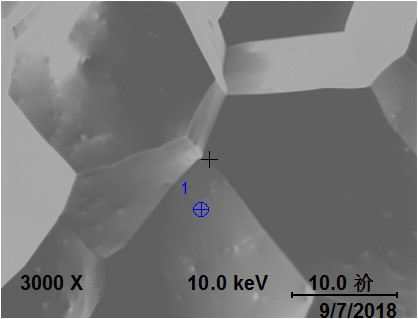

以含Ni还原钼粉为原料,采用冷等静压将粉末压制成棒,经氢气气氛中高温烧结获得钼块体,烧结温度为1900℃,保温时间为6h。测试杂质元素Ni在钼烧结体中的分布规律。AES采集方案:将样品破坏露出新鲜断面,放入纳米扫描俄歇系统中,采用同轴电子枪和CMA能量分析器,电子枪高压为10KV,分析室真空度优于为3.9×10-9 Torr。

Taking Ni-containing reduced molybdenum powder as the raw material, cold isostatic pressing is used to press the powder into a rod, and the molybdenum block is obtained by high-temperature sintering in a hydrogen atmosphere. The sintering temperature is 1900°C and the holding time is 6 hours. Test the distribution of impurity element Ni in the molybdenum sintered body. AES acquisition scheme: Destroy the sample to expose the fresh section, put it into the nano-scan Auger system, use the coaxial electron gun and CMA energy analyzer, the high voltage of the electron gun is 10KV, and the vacuum degree of the analysis chamber is better than 3.9×10-9 Torr.