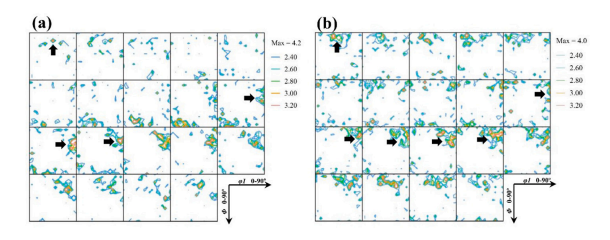

首先采用冷等静压-烧结的方法制备了纯钨板坯,随后进行单向轧制,取样90%形变量的轧板。试样从轧制板材上切割下来,并在管式炉内进行不同温度退火(1100–1500◦C),管式炉中通入高纯氩气进行保护。使用配备电子背散射衍射(EBSD、AZtec系统、牛津仪器)的场发射枪扫描电子显微镜(FE-SEM、JIB 4600F)对微观结构进行表征。对于每个轧制压下板,在TD视图(垂直于横向的平面)中进行观察。对EBSD样品进行机械抛光,然后在环境温度下用2.0 wt%NaOH水溶液在5.0 V下进行电解抛光。然后通过HKL Channel 5软件进行晶粒尺寸、织构分析。通过X射线衍射(XRD)分析轧板表面的宏观织构,采用Cu kα1辐射的背向反射模式。晶界平面分布(GBPD)由XRD数据导出,定量分析所选晶界的晶界平面取向分布,在欧拉空间中构造了取向分布函数(ODF)。

First, a pure tungsten slab was prepared by cold isostatic pressing-sintering method, and then one-way rolling was carried out, and the rolled plate with 90% deformation was sampled. The sample was cut from the rolled plate and annealed at different temperatures (1100–1500 ◦C) in a tube furnace. The tube furnace was protected by high-purity argon gas. A field emission gun scanning electron microscope (FE-SEM, JIB 4600F) equipped with electron backscatter diffraction (EBSD, AZtec system, Oxford Instruments) was used to characterize the microstructure. For each rolling reduction plate, observe in the TD view (a plane perpendicular to the transverse direction). The EBSD samples were mechanically polished and then electrolytically polished with 2.0 wt% NaOH aqueous solution at 5.0 V at ambient temperature. Then use HKL Channel 5 software to analyze the grain size and texture. X-ray diffraction (XRD) was used to analyze the macro-texture on the surface of the rolled sheet, and the back reflection mode of Cu kα1 radiation was used. The grain boundary plane distribution (GBPD) is derived from XRD data, and the grain boundary plane orientation distribution of the selected grain boundary is quantitatively analyzed, and the orientation distribution function (ODF) is constructed in Euler space.