选取三种氧含量分别为140ppm、280ppm、410ppm的FGH96高温合金为材料,按Φ10×15mm加工成热压缩试样,使用电子分析天平精确称重,确保试样质量符合实验要求。将高温合金试样放置在Gleeble热模拟实验机上,在不同温度(1040℃、1070℃、1100℃、1140℃)和应变速率(0.001 s⁻¹、0.01 s⁻¹、0.1 s⁻¹、1 s⁻¹)条件下进行热压缩实验,选取开裂较为严重而而压缩样品,本实验选用的是应变温度为1070℃、应变速率为1-s的样品。用800#、1200#和2000#砂纸逐级进行细磨,最后进行机械抛光、电解抛光、电解腐蚀。其中电解抛光所用的电解抛光液为:20vol.%硫酸+80vol.%甲醇,电解抛光电压为:15V,电解15s;电解腐蚀所用的电解腐蚀液为:170ml磷酸+10ml硫酸+15gCrO3,电解腐蚀电压为:2-5V,电解2-3s。采用配有能谱仪的ZEISS Sigma 300场发射扫描电镜分析金相试样表面的流动失稳组织。

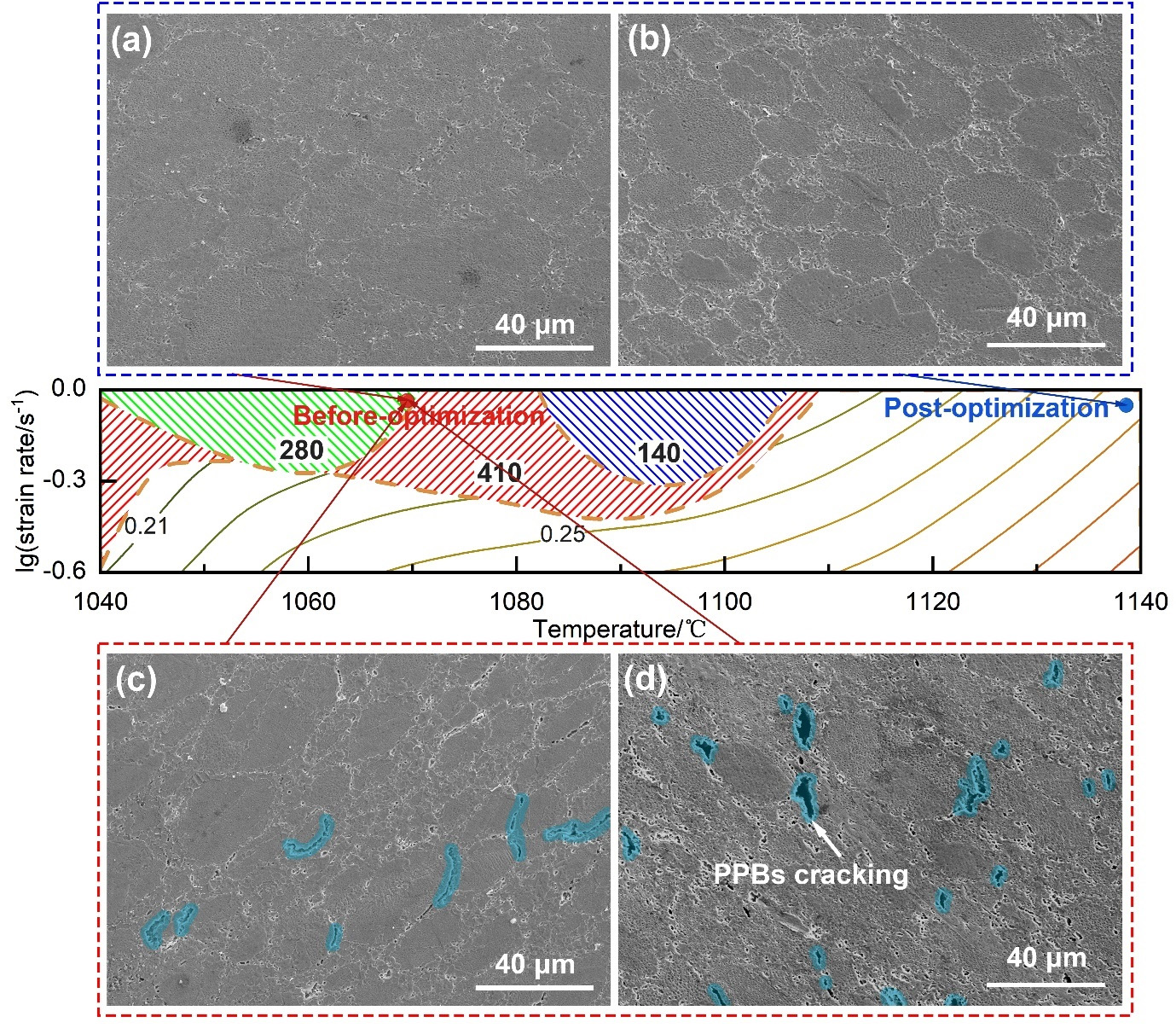

Three types of FGH96 superalloys with oxygen contents of 140ppm, 280ppm and 410ppm respectively were selected as materials and processed into hot-compressed samples with diameters of Φ10×15mm. The samples were precisely weighed using an electronic analytical balance to ensure that the sample quality met the experimental requirements. The superalloy specimens were placed on the Gleeble thermal simulation testing machine and subjected to hot compression tests under different temperatures (1040℃, 1070℃, 1100℃, 1140℃) and strain rates (0.001 s⁻¹, 0.01 s⁻¹, 0.1 s⁻¹, 1 s⁻¹). The compressed samples with more severe cracking were selected. The samples selected for this experiment have a strain temperature of 1070℃ and a strain rate of 1-s. Fine grinding was carried out step by step with 800#, 1200# and 2000# sandpapers, and finally mechanical polishing, electrolytic polishing and electrolytic etching were performed. Among them, the electrolytic polishing solution used for electrolytic polishing is: 20vol.% sulfuric acid +80vol.% methanol, the electrolytic polishing voltage is: 15V, and the electrolysis lasts for 15 seconds. The electrolytic corrosion solution used in electrolytic corrosion is: 170ml of phosphoric acid +10ml of sulfuric acid +15g of cro3. The electrolytic corrosion voltage is: 2-5V, and the electrolysis lasts for 2-3 seconds. The flow-unstable microstructure on the surface of metallographic specimens was analyzed by using a ZEISS Sigma 300 field emission scanning electron microscope equipped with an energy spectrometer.