将三种HIP态的高温合金通过线切割的方式取样。用400#砂纸进行粗磨,然后用800#、1200#和2000#砂纸逐级进行细磨,最后进行机械抛光、电解抛光、电解腐蚀。其中电解抛光所用的电解抛光液为:20vol.%硫酸+80vol.%甲醇,电解抛光电压为:15V,电解15s;电解腐蚀所用的电解腐蚀液为:170ml磷酸+10ml硫酸+15gCrO3,电解腐蚀电压为:2-5V,电解2-3s。采用配有能谱仪的ZEISS Sigma 300场发射扫描电镜分析金相试样表面的微观形貌。

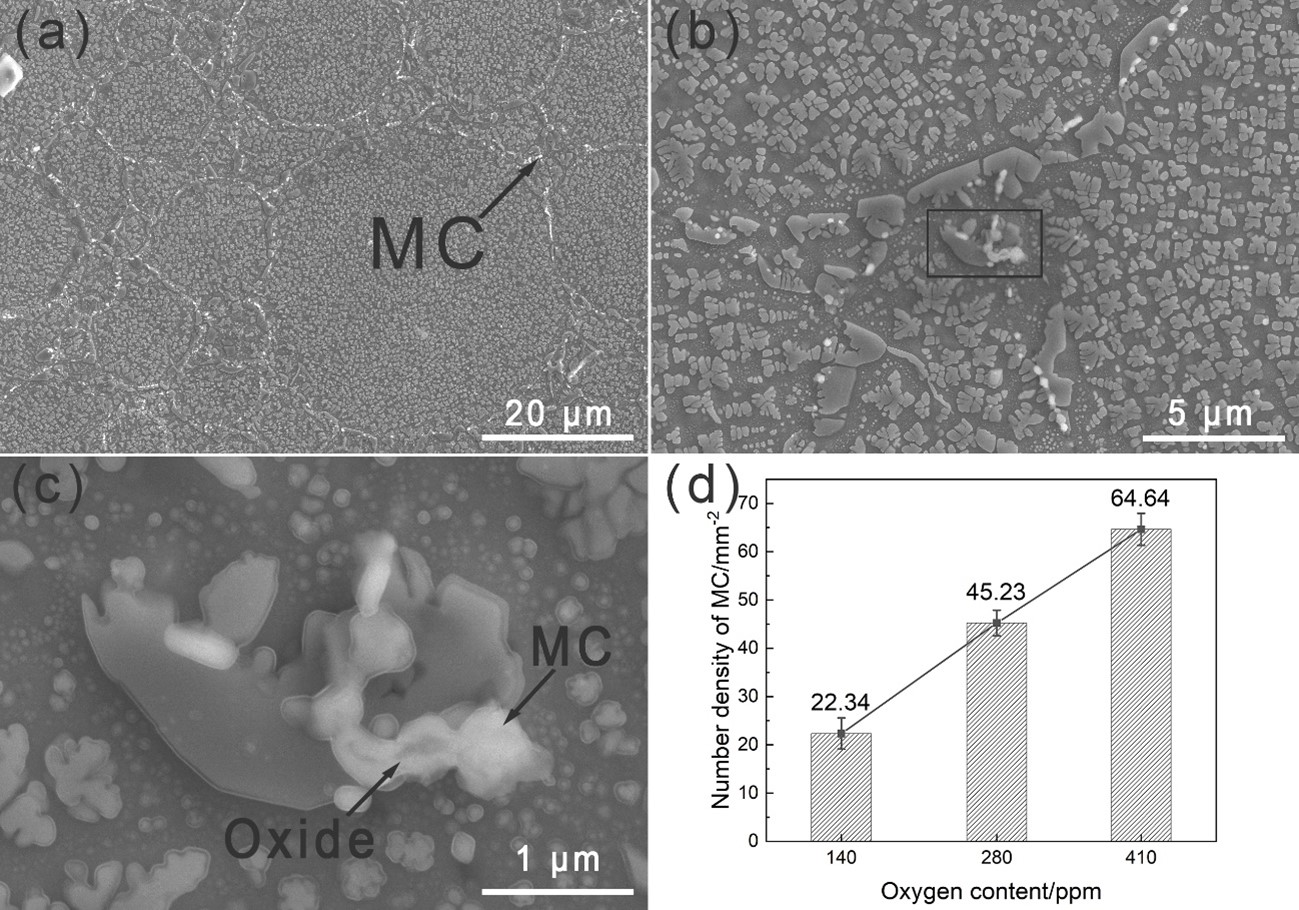

Samples of the three HIP state superalloys were taken by wire cutting. Rough grinding is carried out with 400# sandpaper, followed by fine grinding step by step with 800#, 1200# and 2000# sandpapers. Finally, mechanical polishing, electrolytic polishing and electrolytic etching are performed. Among them, the electrolytic polishing solution used for electrolytic polishing is: 20vol.% sulfuric acid +80vol.% methanol, the electrolytic polishing voltage is: 15V, and the electrolysis lasts for 15 seconds. The electrolytic corrosion solution used in electrolytic corrosion is: 170ml of phosphoric acid +10ml of sulfuric acid +15g of cro3. The electrolytic corrosion voltage is: 2-5V, and the electrolysis lasts for 2-3 seconds. The microscopic morphology of the surface of metallographic specimens was analyzed by using a ZEISS Sigma 300 field emission scanning electron microscope equipped with an energy spectrometer.