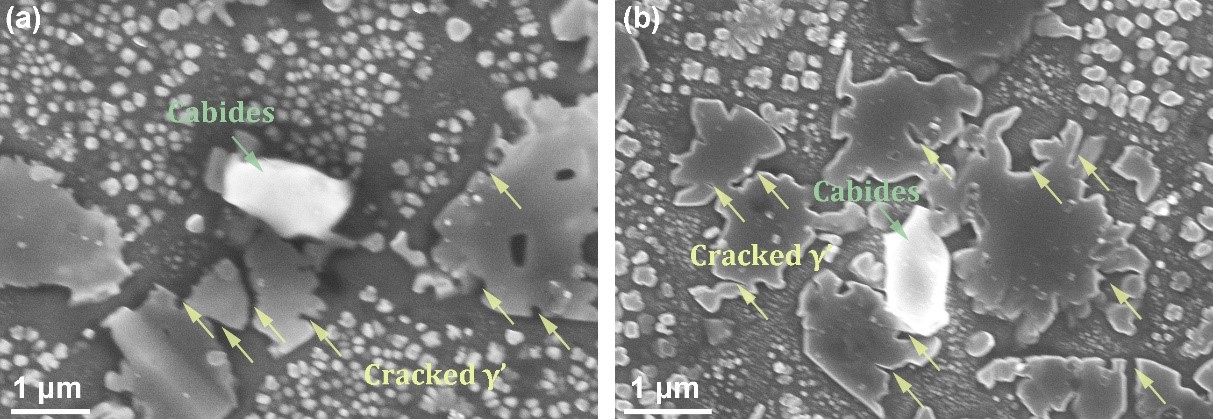

等温锻造态蠕变失效后FGH96合金为研究对象,测试不同氧含量对HIF态合金相及晶粒组织孔洞形核的影响规律。SEM及EBSD采集方案:对蠕变失效后的HIF态合金样品表面进行机械研磨和机械抛光,随后电解抛光,电解抛光液成分为20vol.%H2SO4+80vol.%CH3OH。HIF态试样电抛电压为 15V、时间为 10s,进行电解抛光。通过EDAX配置的电子背散射衍射(EBSD)进行测量。通过AztecCrystal软件对EBSD数据进行处理,分析不同氧含量FGH96合金粉末在烧结过程中产生的晶粒组织及细晶去的生成机理。TEM采集方案:通过机加工线切割切HIF态合金约 0.3mm 厚的薄片,并研磨至 40~50μm,使用电解双喷减薄仪进行减薄。通过TEM对不同氧含量HIF态合金进行观察,分析氧含量的变化对合金PPB界面再结晶晶粒的影响。

FGH96 alloy after creep failure in isothermal forging was used as the research object to test the effect of different oxygen content on the phase and grain structure of HIF alloy. SEM and EBSD acquisition schemes: The surface of HIF alloy samples after creep failure was mechanically ground and polished, followed by electrolytic polishing. The electrolytic polishing liquid composition was 20vol.%H2SO4+80vol.%CH3OH. Electrolytic polishing was carried out for HIF state samples with electric throwing voltage of 15V and time of 10s. The measurements were made by electron backscatter diffraction (EBSD) in the EDAX configuration. The EBSD data were processed by AztecCrystal software to analyze the grain structure and the formation mechanism of fine crystal removal of FGH96 alloy powder with different oxygen content during sintering. TEM acquisition scheme: HIF alloy slices of about 0.3mm thick were cut by machining wire, and ground to 40~50μm, and thinned by electrolytic double-spray thinning instrument. The effect of oxygen content on the recrystallization grains at PPB interface of HIF alloy was observed by TEM.