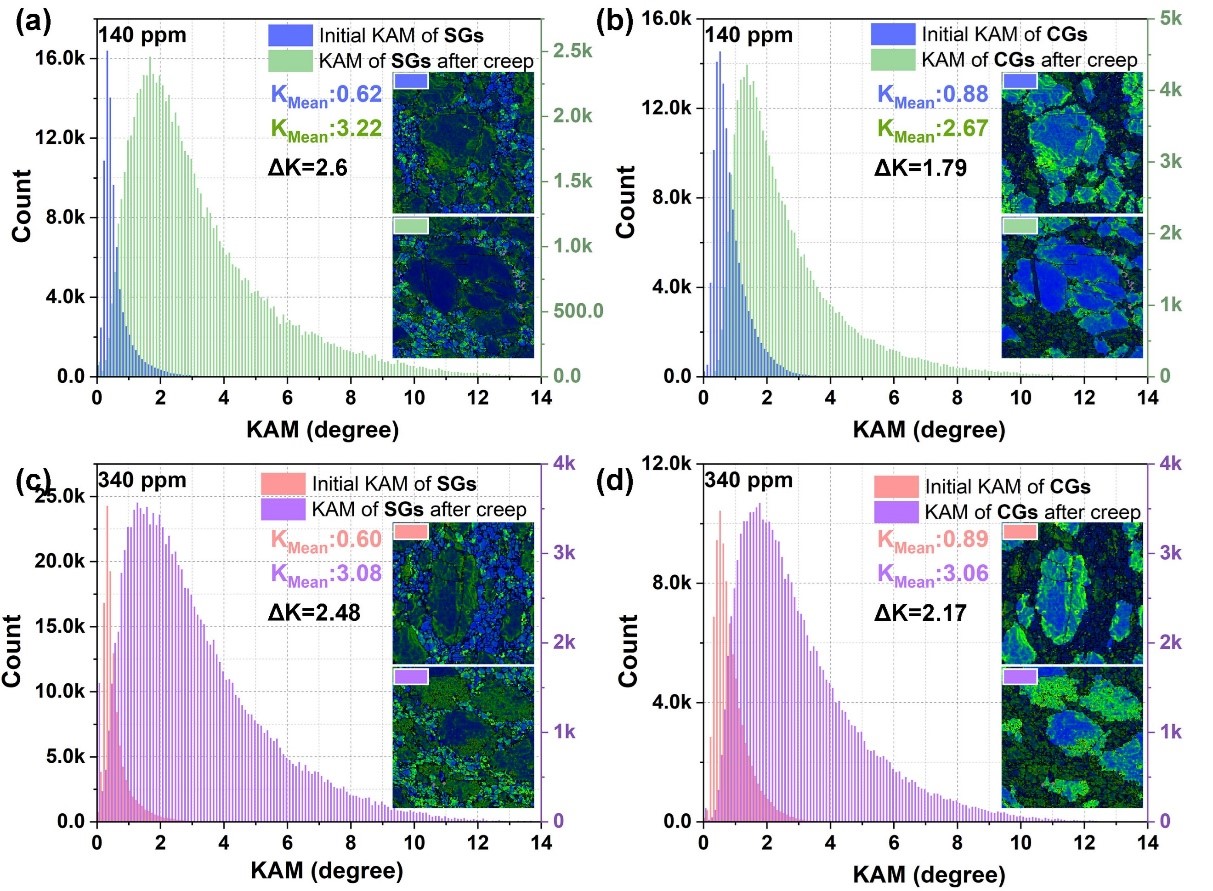

以蠕变后HIF态FGH96合金为研究对象,测试不同氧含量对蠕变后合金晶粒组织的影响。EBSD采集方案:对样品表面进行机械研磨和机械抛光,随后电解抛光,电解抛光液成分为20vol.%H2SO4+80vol.%CH3OH。HIF态试样电抛电压为 15V、时间为 10s,进行电解抛光。通过EDAX配置的电子背散射衍射(EBSD)进行测量。通过AztecCrystal软件对EBSD数据进行处理,分析不同氧含量FGH96合金粉末在烧结过程中产生的晶粒组织。

The effect of different oxygen content on grain structure of HIF FGH96 alloy after creep was tested. EBSD collection protocol: Mechanical grinding and mechanical polishing of the sample surface, followed by electrolytic polishing, electrolytic polishing liquid composition of 20vol.%H2SO4+80vol.%CH3OH. Electrolytic polishing was carried out for HIF state samples with electric throwing voltage of 15V and time of 10s. The measurements were made by electron backscatter diffraction (EBSD) in the EDAX configuration. The EBSD data were processed by AztecCrystal software to analyze the grain structure of FGH96 alloy powder with different oxygen content during sintering.