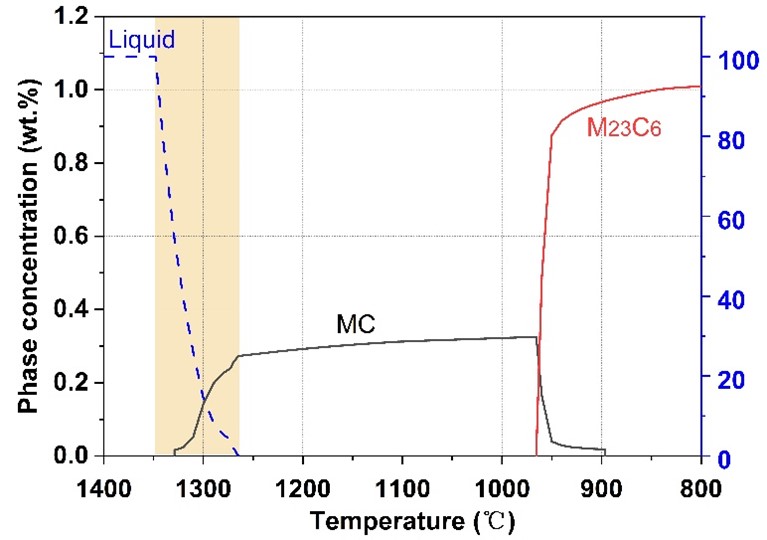

结合TEM下烧结颈部分碳化物与氧化物颗粒的相位关系,分析在烧结过程中氧化物颗粒与碳化物颗粒的生长机理。通过在雾化制粉由液相凝固过程中碳化物析出的热力学计算,分析原始合金粉末颗粒表面碳化物与烧结过程中PPB界面碳化物的遗传演变关系,并结合Photoshop软件绘制烧结过程中碳化物包裹氧化物颗粒核壳状结构的形成机理。

By means of discharge plasma sintering (SPS furnace), rapid interrupt sintering experiment was carried out to prepare sintering neck samples at different sintering stages. The sample size is φ10×10 mm. The sintering atmosphere is vacuum, the sintering temperature is 1000℃, and the sintering pressure is 10 MPa-5 min. The sintering neck was cut by FIB technology, and the phase relationship between carbide and oxide particles was observed by TEM. The growth mechanism of oxide particles and carbide particles during sintering was analyzed.