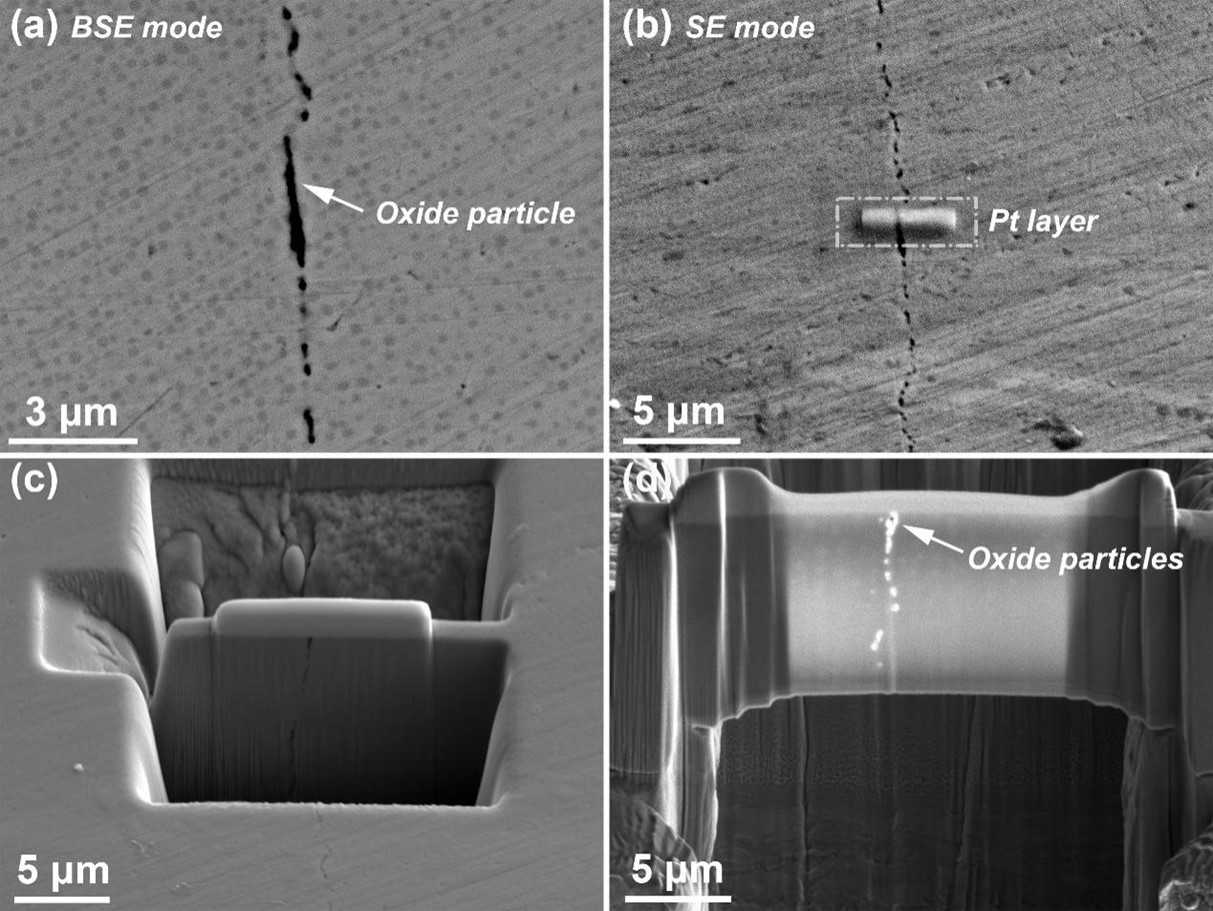

以北京航空材料研究院提供的铸态FGH96合金锭为原材料,通过电火花线切割取φ10×10 mm的圆柱状样品,借助金相抛光机进行金相制样。对圆柱状样品在管式炉中空气气氛下预氧化形成氧化表面,氧化温度为500℃,氧化时间为30min。将两个氧化表面对接并通过SPS烧结连接制备扩散偶界面。烧结温度为1000℃,烧结时间为5min。将扩散偶样品真空封装在石英管中进行不同时间的热处理。通过FIB切割扩散偶界面TEM样品,对热处理不同时间的扩散偶界面进行TEM观察,分析扩散偶界面氧化物颗粒相的溶解行为,以及γ′的粗化行为。

Using as-cast FGH96 alloy ingot provided by Beijing Institute of Aeronautical Materials as raw material, cylindrical samples of φ10×10 mm were taken by EDM wire cutting, and metallographic samples were prepared by metallographic polishing machine. The cylindrical sample was pre-oxidized to form an oxidizing surface in an air atmosphere in a tube furnace at an oxidation temperature of 500℃ and an oxidation time of 30min. The two oxidized surfaces were jointed and connected by SPS sintering to prepare the diffusion-couple interface. The sintering temperature is 1000℃ and the sintering time is 5min. The diffused couple samples were vacuum encapsulated in quartz tubes for heat treatment at different times. The diffusion-couple interface samples were cut by FIB, and the diffusion-couple interface was observed by TEM at different heat treatment times. The dissolution behavior and coarsening behavior of oxide particles at diffusion-couple interface were analyzed.