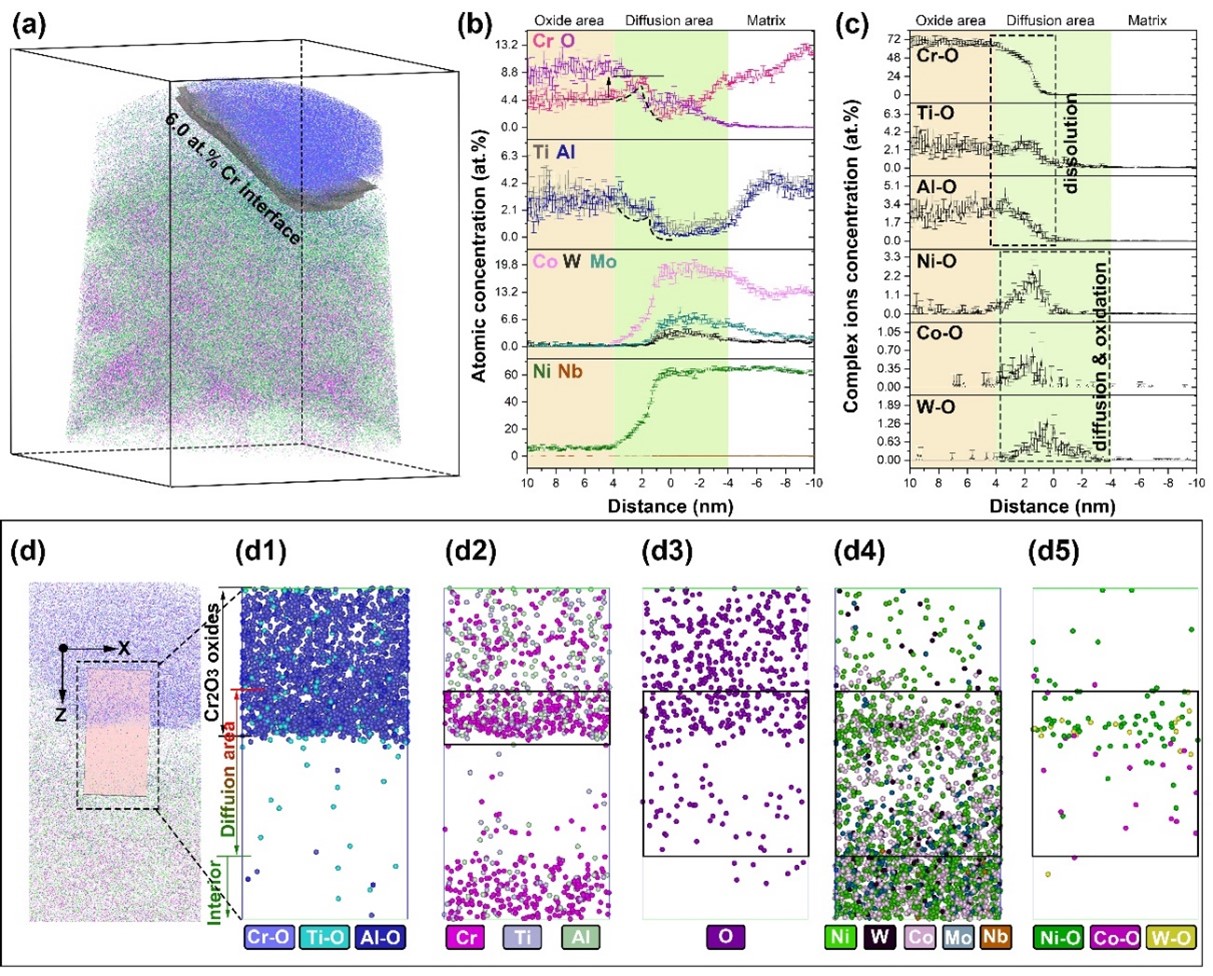

首先采用FIB技术切取原始FGH96高温合金粉末表面氧化层TEM样品,在STEM(Talos F200 GX)模式下对氧化层进行EDS线扫,分析合金粉末氧化层厚度及元素在氧化层内的分布规律。烧结初期阶段的烧结颈样品具有两种形貌:未形成烧结颈的孔洞区域;烧结颈区域。采用FIB技术分别对这两种区域进行TEM取样。在STEM(Talos F200 GX)模式下对这两种区域进行EDS线扫,分析氧在未形成烧结颈时的扩散行为及在形成烧结颈后转变为氧化物颗粒的演变规律。

First, the TEM samples of the oxide layer on the surface of the original FGH96 superalloy powder were cut by FIB technique, and the oxide layer was subjected to EDS line scanning in STEM (Talos F200 GX) mode to analyze the oxide layer thickness of the alloy powder and the distribution of elements in the oxide layer. The sintered neck samples in the initial stage of sintering have two kinds of morphology: the cavity region without sintered neck; Sintering neck area. The two areas were sampled by TEM using FIB technology. EDS line scanning was performed in STEM (Talos F200 GX) mode to analyze the diffusion behavior of oxygen before the formation of sintering neck and the evolution law of oxygen transformed into oxide particles after the formation of sintering neck.