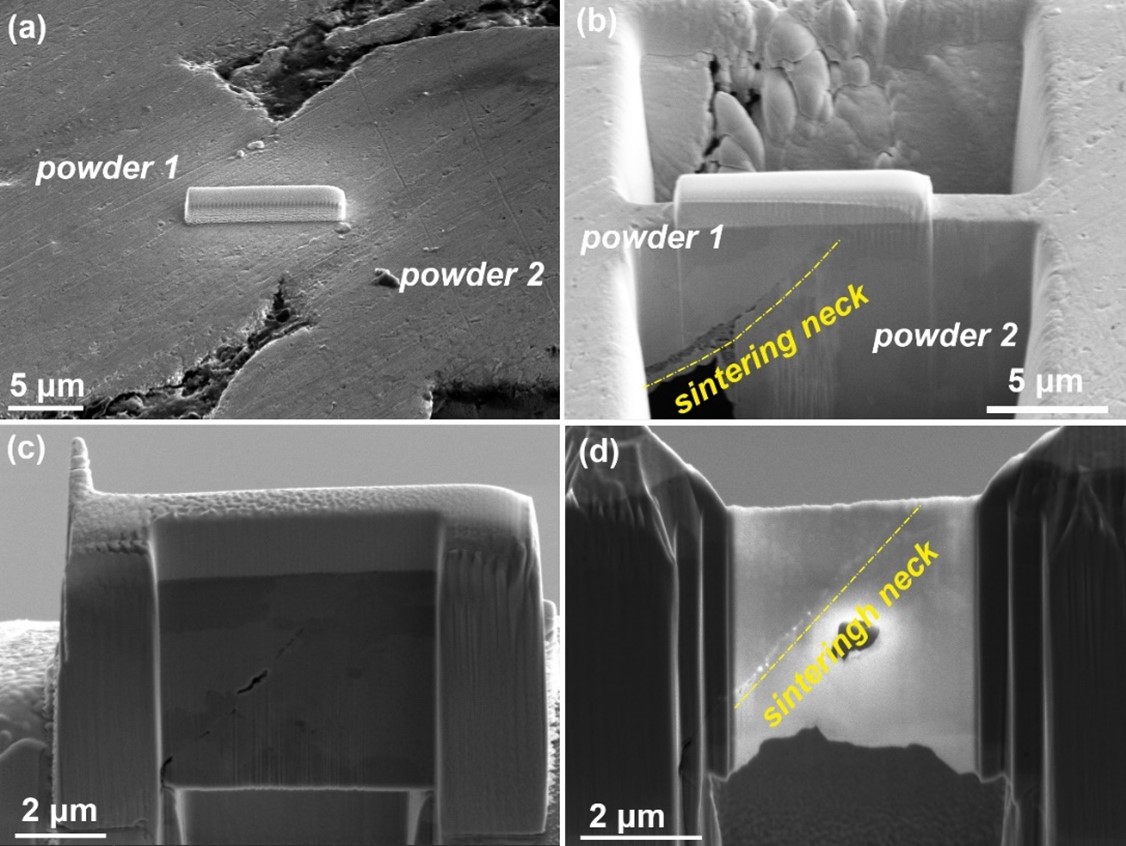

为研究合金粉末氧化层在烧结过程中的演变规律,使用粒径~40 μm等粒度的FGH96高温合金粉末,借助放电等离子烧结(SPS炉)进行快速的中断烧结实验,制备出不同烧结阶段的烧结颈样品。样品尺寸为φ10×10 mm。烧结气氛为真空,烧结温度为1000℃,烧结压力及时为10 MPa-5 min。借助SEM观察在烧结过程中烧结颈形貌的演变规律。借助FIB技术切取烧结阶段的烧结颈,通过TEM观察烧结颈部分形貌。

In order to study the evolution law of the oxide layer of alloy powder during sintering, FGH96 superalloy powder with particle size ~ 40μm was used to conduct rapid interrupt sintering experiment by means of discharge plasma sintering (SPS) furnace, and sintering neck samples at different sintering stages were prepared. The sample size is φ10×10 mm. The sintering atmosphere is vacuum, the sintering temperature is 1000℃, and the sintering pressure is 10 MPa-5 min. The evolution of the neck morphology during sintering was observed by SEM. The sintered neck was cut by FIB technique and the morphology of the sintered neck was observed by TEM.