本研究搭建了基于前反馈神经网络方法的智能监测和诊断模型,以实现SIMONS系统稳态运行时多物理量间非线性关系的预测和控制。采用堆芯在不同功率水平下稳态运行时的反应性水平、堆芯出口温度、流量等参数对智能模块开展训练,建立了智能监测和诊断模块。采用不同功率水平下堆内速度、温度和压力分布数据对智能监测模块开展训练。基于循环神经网络和长短时记忆网络方法建立了智能调节和决策模块。采用堆芯变功率过程中反应性水平、堆芯出口温度、流量等瞬态变量对智能模块开展训练,建立了智能调节模块。智能调节模块可对堆芯功率水平、堆芯出口温度、堆内反应性水平实现准确预测和控制。采用反应堆紧急停堆过程中反应性水平、堆芯出口温度、包壳温度等参数对智能决策模块开展训练,建立了紧急停堆智能决策模块。紧急停堆智能决策模块可对紧急停堆过程中堆内反应性水平、基体温度、包壳温度等关键参数的预测和控制,实现对SIMONS系统的超温和超功率时的及时保护。 基于自动机器学习方法建立智能控制系统,以实现SIMONS动力系统内堆芯、透平、回热器以及压气机等主要设备的相关参数实现预测和控制。经训练后,该智能控制系统可对SIMONS动力系统在未期功率水平阶跃变化过程中的堆芯反应性水平、堆芯出口温度和透平出口温度等关键参数实现准确预测和控制。经训练,该智能控制系统可对不同始发事件引发紧急停堆时堆内反应性水平、透平出口温度等关键参数的预测和控制。

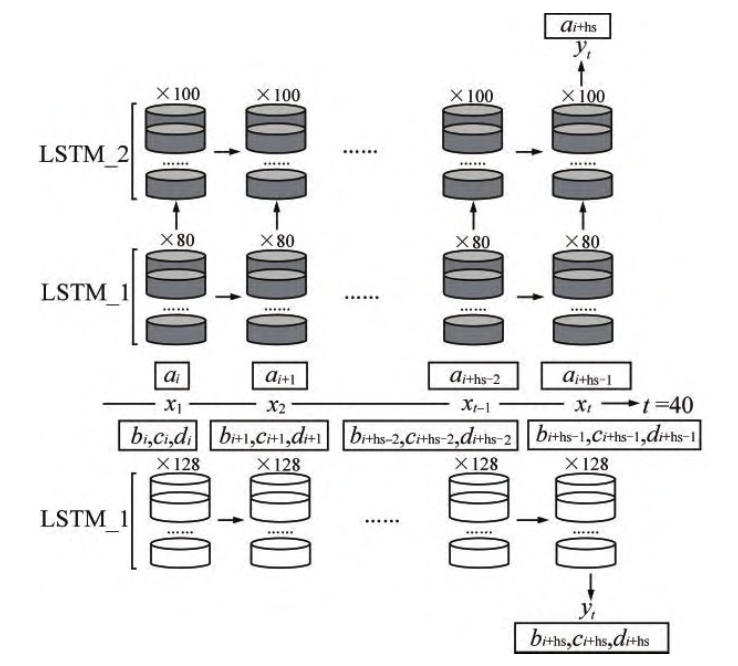

In order to predict and control the physical quantities of the SIMONS system, an intelligent monitoring and diagnosis model based on forward feedback neural network method is established. The intelligent module is trained by reactor core reactivity, reactor core outlet temperature, flow and other parameters during steady-state operation at different power levels. The intelligent monitoring and diagnosis module is trained with numerical results of velocity, temperature and pressure distributions in the rector. Based on the methods of the recurrent neural network (RNN) and the long and short-term memory network (LSTM), the intelligent control and decision module is established considering the characteristic of time-varying nonlinear process and the coupling of multi-scale physical quantities. The trained intelligent regulation module can accurately predict and control the core power level, core outlet temperature and reactor reactivity level. This intelligent decision module can predict and control the reactor reactivity level, reactor core temperature, cladding temperature and other key parameters in the case of emergency shutdown. Based on the automatic machine learning method, an intelligent control system is established to realize the prediction and control of relevant parameters of main equipment such as reactor core, turbine, recuperator and compressor in SIMONS power system. Numerical results of reactor core reactivity level, outlet temperature and turbine outlet temperature during different power adjustment are used to train the intelligent control system. After the training process, the intelligent control system can accurately predict and control the reactor core reactivity level, core outlet temperature and turbine outlet temperature of SIMONS power system during the unpredicted power level change. With different accident scenarios, the intelligent control system is trained by numerical results of reactor core reactivity level, core outlet temperature and turbine outlet temperature in SIMONS power system caused by different accidents.