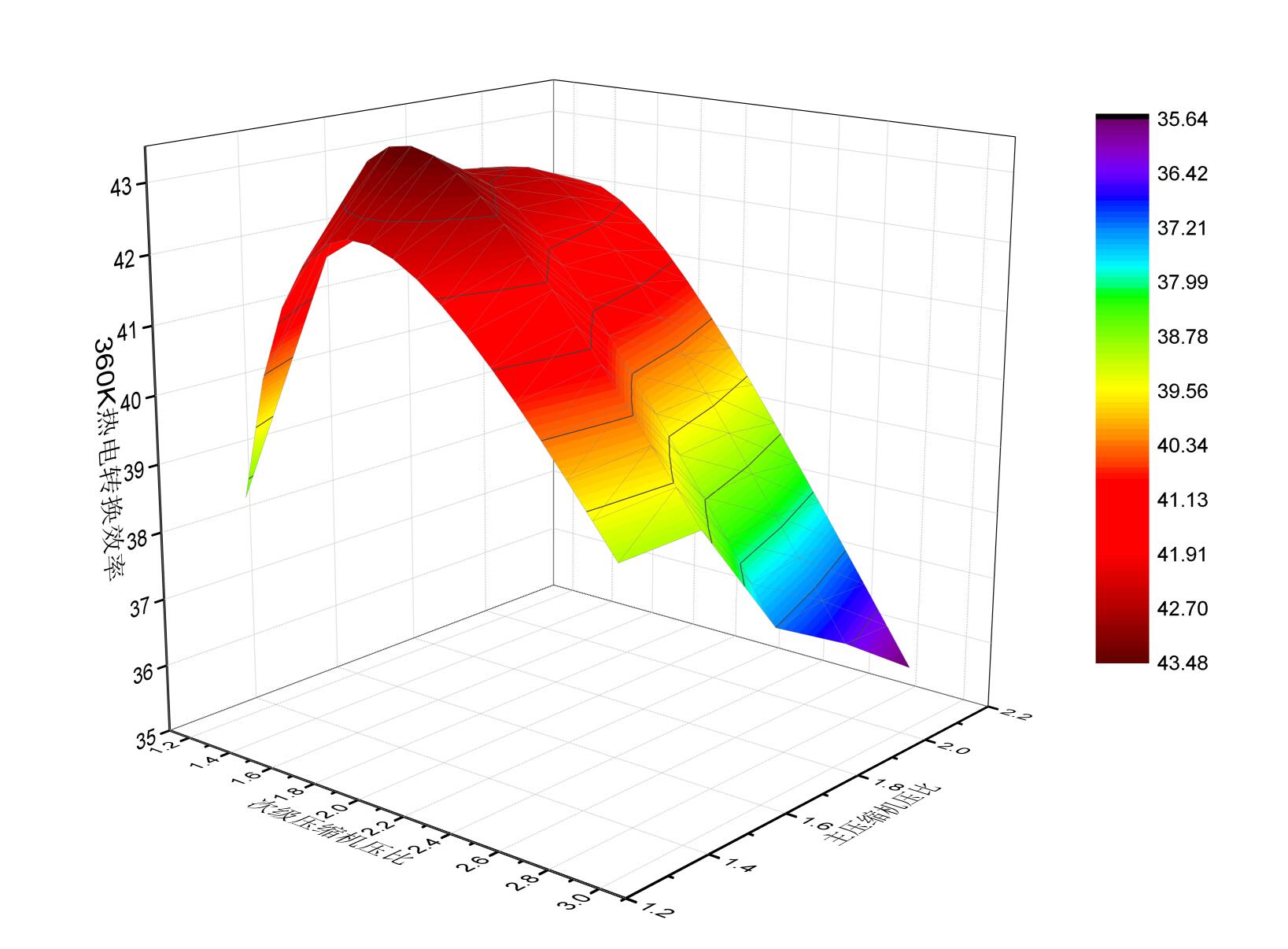

系统最低温度为360 K对IRC和的影响,最佳摩尔质量为40g/mol,最高操作温度和压力分别为1273 K和1.36 MPa。结果表明,随着PR的增加,热效率先上升后下降。这一趋势可归因于压缩机功和PR之间的线性关系,而透平做功呈现出快速增加后的平稳期。此外,由于预冷器的出口温度的降低导致压缩机功的降低,而涡轮机功在最高系统温度下保持恒定,因此预冷器出口温度的下降导致热效率的提高。

The minimum temperature of the system is 360 K, and the optimal molar mass is 40g/mol. The maximum operating temperature and pressure are 1273K and 1.36MPa, respectively. The results indicate that with the increase of PR, the thermal efficiency first increases and then decreases. This trend can be attributed to the linear relationship between compressor work and PR, while the turbine work shows a stable period after a rapid increase. In addition, the decrease in outlet temperature of the precooler leads to a decrease in compressor power, while turbine power remains constant at the highest system temperature. Therefore, the decrease in outlet temperature of the precooler leads to an improvement in thermal efficiency.