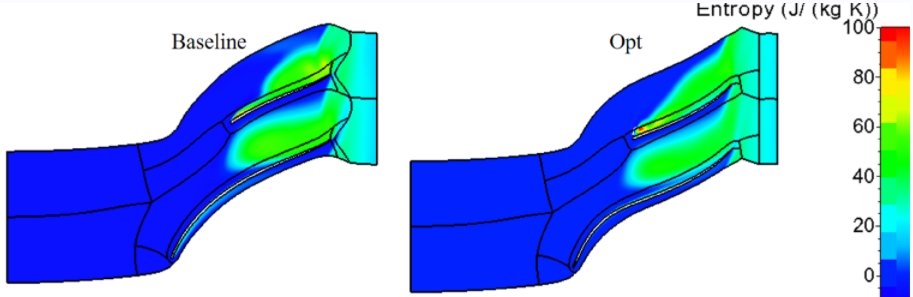

研究结果表明,上壁面的熵值增加主要在流动方向的后半部分,工质流出叶轮出口后在无叶扩压器中由于周向速度低于叶轮出口,流动会向下游偏移,高熵的低能流体由于没有完全掺混,造成图中的叶轮出口上壁面熵值呈高低分布规律的现象。上壁面出现的熵值较低区域是因为叶片压力面低熵流体从叶顶间隙涌入到上壁面附近。三种方案对比可以观察到,经过优化之后,叶轮上壁面的熵值已经减小,上端壁泄漏流得到明显的改善,这也是优化叶片效率上升的主要原因之一。

The research results show that the increase of entropy on the upper wall is mainly in the latter half of the flow direction. After the working fluid flows out of the impeller outlet, the flow in the vaneless diffuser will shift to the downstream because the circumferential velocity is lower than that at the impeller outlet. Because the low-energy fluid with high entropy is not completely mixed, the entropy on the upper wall of the impeller outlet in the figure shows a high and low distribution law. The low entropy area on the upper wall is due to the low entropy fluid on the blade pressure surface pouring into the upper wall from the tip clearance. Compared with the three schemes, it can be observed that after optimization, the entropy of the upper wall of the impeller has been reduced, and the leakage flow of the upper wall has been significantly improved, which is one of the main reasons for the increase of the efficiency of the optimized blade.