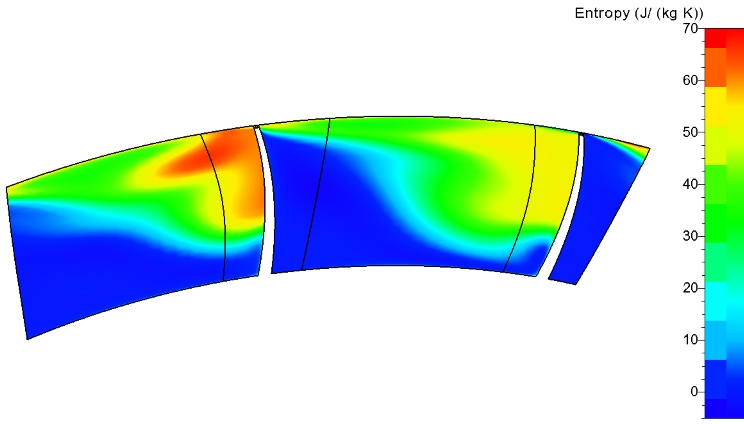

在轮盖一侧熵增明显,由于叶轮尺寸较小,尤其在动叶出口处,叶片高度较低,叶顶间隙占流道高度增加,会有相当一部分工质从叶顶间隙进入相邻的流道,这股泄露流会干扰主流的流动,造成熵增。而且由于泄露流的扰动和逆压流动,轮盖侧边界层发生滞止、倒流、流动紊乱现象,产生边界层分离。从熵云图中可以看到分离区域沿着流动方向迅速发展,整个出口均处在熵增区域,可能进一步产生尾迹损失、内泄露损失。由于上壁面位置流动损失严重,造成级效率偏低。

On one side of the wheel cover, entropy increases obviously. Due to the small size of the impeller, especially at the outlet of the rotor blade, the blade height is low, and the tip clearance occupies an increased height of the flow channel, a considerable part of the working fluid will enter the adjacent flow channel from the tip clearance, and this leakage flow will interfere with the flow of the main stream, resulting in an increase in entropy. Moreover, due to the disturbance of leakage flow and reverse pressure flow, the boundary layer of the wheel cover side has stagnation, backflow and flow disturbance, resulting in boundary layer separation. From the entropy cloud image, it can be seen that the separation area develops rapidly along the flow direction, and the entire outlet is in the area of entropy increase, which may further produce wake loss and internal leakage loss. Due to the serious flow loss on the upper wall, the stage efficiency is low.