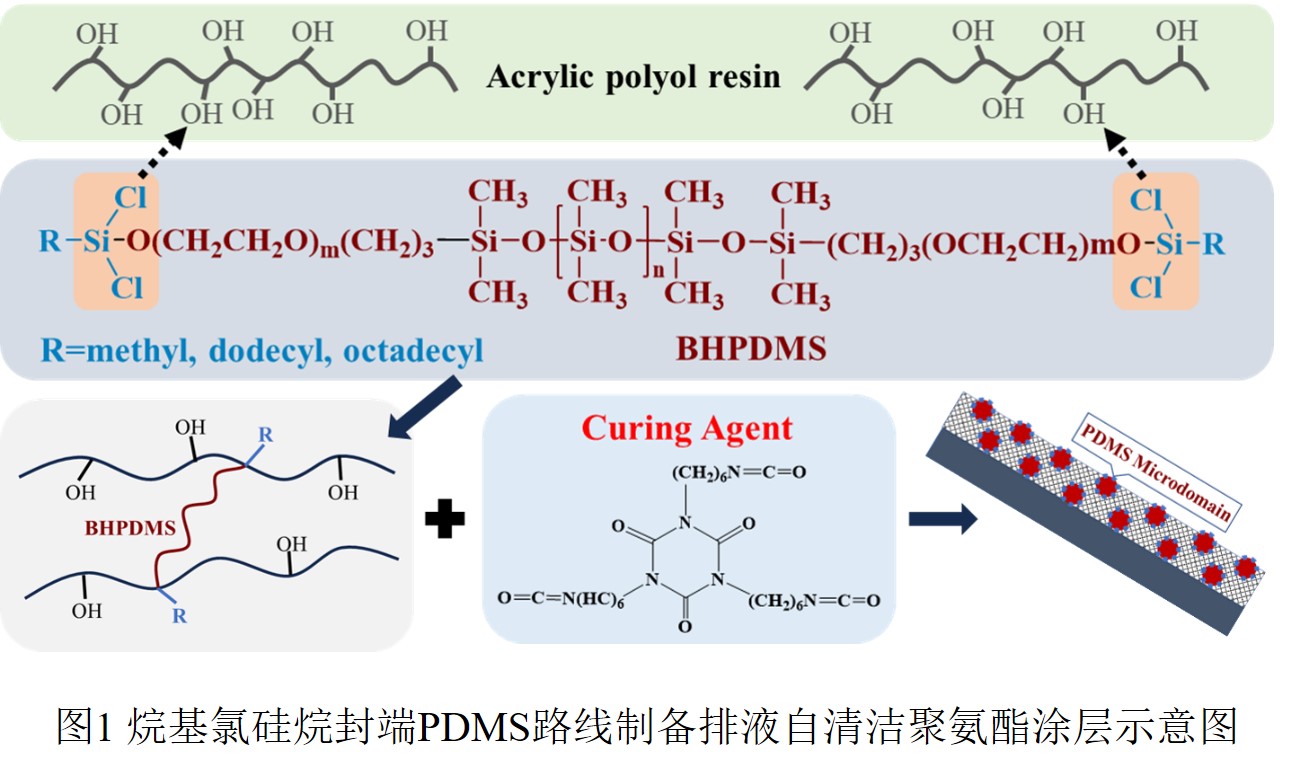

利用烷基三氯硅烷封端双羟基PDMS,再将其与羟基丙烯酸树脂反应,将PDMS化学键合至丙烯酸树脂链段上,然后与异氰酸酯固化剂固化得到排液自洁涂层。具体制备过程如下:将烷基三氯硅烷(MTS、DTS、OTS)和双羟丙基聚二甲基硅氧烷(BHPDMS)(Mn=1000、2000、4300 g/mol)以2:1的摩尔比混合,然后溶解在质量是其两倍的二甲苯溶剂中。密封搅拌30分钟后,不密封继续搅拌4小时以确保所有羟基反应完全。当气泡停止产生后,将所得产物以特定比例加入到SM515树脂中继续搅拌24小时。随后与固化剂N3390混合,并引入总质量0.05 wt%的催化剂DBTDL制备出复合树脂,将其搅拌均匀后均匀涂覆到玻璃片上并在120°C下进一步固化4小时。为了进行比较,必须确保所有实验中烷基三氯硅烷和BHPDMS的总质量保持不变。

Using alkyl trichlorosilane to terminate dihydroxyPDMS, it is then reacted with hydroxyacrylic resin to chemically bond PDMS onto acrylic resin segments, and then cured with isocyanate curing agent to obtain a self-cleaning coating for drainage. The specific preparation process is as follows: alkyl trichlorosilane (MTS, DTS, OTS) and dihydroxypropyl polydimethylsiloxane (BHPDMS) (Mn=1000, 2000, 4300 g/mol) are mixed in a 2:1 molar ratio, and then dissolved in a xylene solvent twice its mass. After sealing and stirring for 30 minutes, continue stirring for 4 hours without sealing to ensure complete hydroxyl reaction. After the production of bubbles stops, add the obtained product in a specific proportion to SM515 resin and continue stirring for 24 hours. Subsequently, the composite resin was prepared by mixing with curing agent N3390 and introducing a catalyst DBTDL with a total mass of 0.05 wt%. After stirring evenly, the resin was uniformly coated onto glass sheets and further cured at 120 ° C for 4 hours. For comparison, it is necessary to ensure that the total mass of alkyl trichlorosilane and BHPDMS remains unchanged in all experiments.