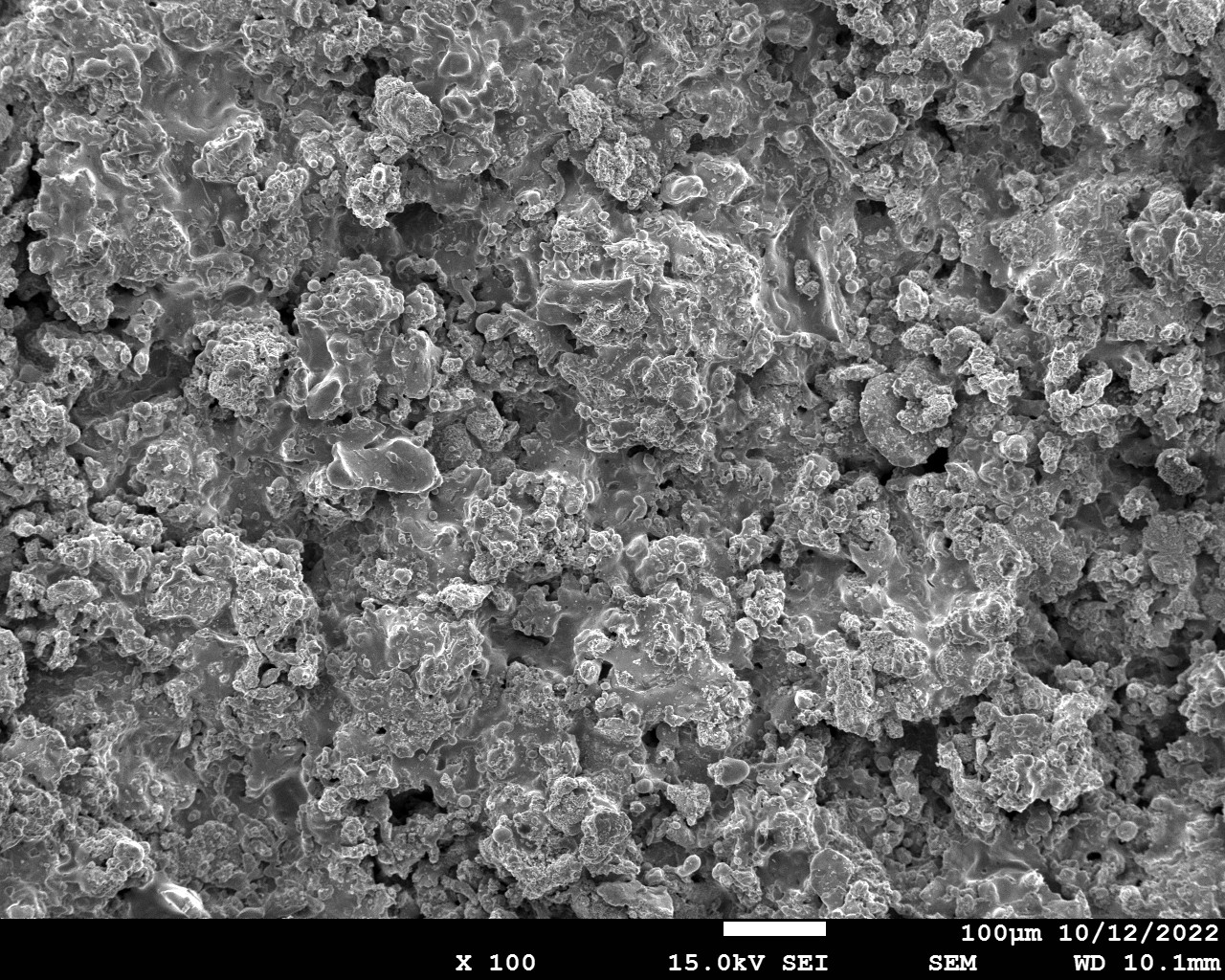

In order to maximize the excellent performance of powders, people usually carry out surface coating treatment on ultrafine powders to improve the surface characteristics of particles and enhance their dispersion performance, in order to meet the requirements of industrial applications. In order to further improve the comprehensive properties such as wear resistance, oxidation resistance and corrosion resistance of materials required for repairing critical parts, we decided to use High-entropy alloy matrix coated ceramic reinforcement to improve the material properties, and prepared CoCrFeNiTi High-entropy alloy and CoCrFeNiTi/cBN, CoCrFeNiTi/SiC, CoCrFeNiTi/WC, CoCrFeNiTi/SiC-Y2O3 and other High-entropy alloy matrix coated ceramic reinforcement composites through ball milling, sintering, crushing and other methods, The coating condition, loose density, particle size and fluidity of ceramic reinforcement phase by High-entropy alloy were characterized. The prepared powder was made into samples by Thermal spraying, laser cladding and other means, and the performance characterization and mechanism analysis of the relevant finished product samples were carried out.