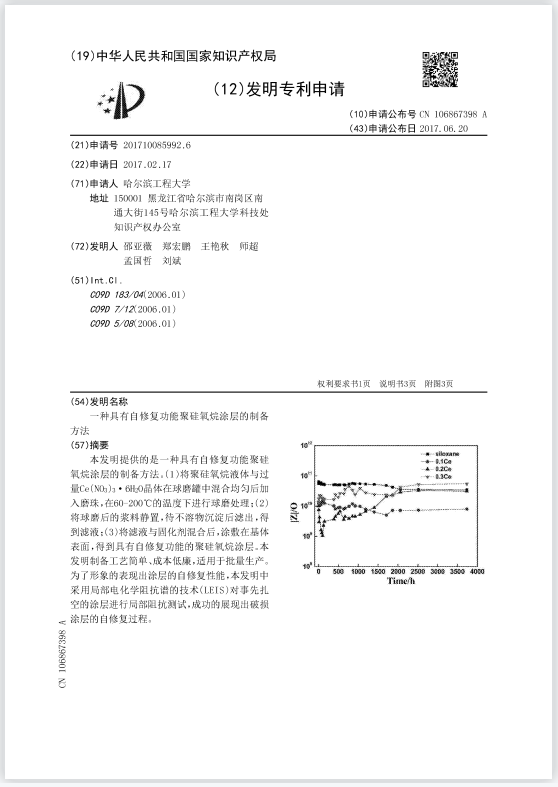

本发明提供的是一种具有自修复功能聚硅氧烷涂层的制备方法。(1)将聚硅氧烷液体与过量Ce(NO3)3·6H2O晶体在球磨罐中混合均匀后加入磨珠,在60‑200℃的温度下进行球磨处理;(2)将球磨后的浆料静置,待不溶物沉淀后滤出,得到滤液;(3)将滤液与固化剂混合后,涂敷在基体表面,得到具有自修复功能的聚硅氧烷涂层。本发明制备工艺简单、成本低廉,适用于批量生产。为了形象的表现出涂层的自修复性能,本发明中采用局部电化学阻抗谱的技术(LEIS)对事先扎空的涂层进行局部阻抗测试,成功的展现出破损涂层的自修复过程。

The invention provides a preparation method of a polysiloxane coating with a self-repairing function. The method comprises the following steps: (1) evenly mixing polysiloxane liquid and excessive Ce(NO3)3.6H2O crystals in a ball-milling tank, then adding grinding balls into the mixture, and carrying out ball-milling treatment at the temperature of 60-200 DEG C; (2) enabling slurry, obtained after the ball-milling treatment is carried out, to stand, and filtering after undissolved substances precipitate so as to obtain filtrate; (3) mixing the filtrate with a curing agent, and then coating the surface of a substrate with the mixture to obtain the polysiloxane coating with the self-repairing function. The preparation method provided by the invention is simple in technology, low in cost and suitable for batch production. In order to visually show the self-repairing performance of the coating, a localized electrochemical impedance spectroscopy (LEIS) technology is adopted to perform a local impedance test on the coating which is punctured in advance, and the self-repairing process of the damaged coating is successfully shown.