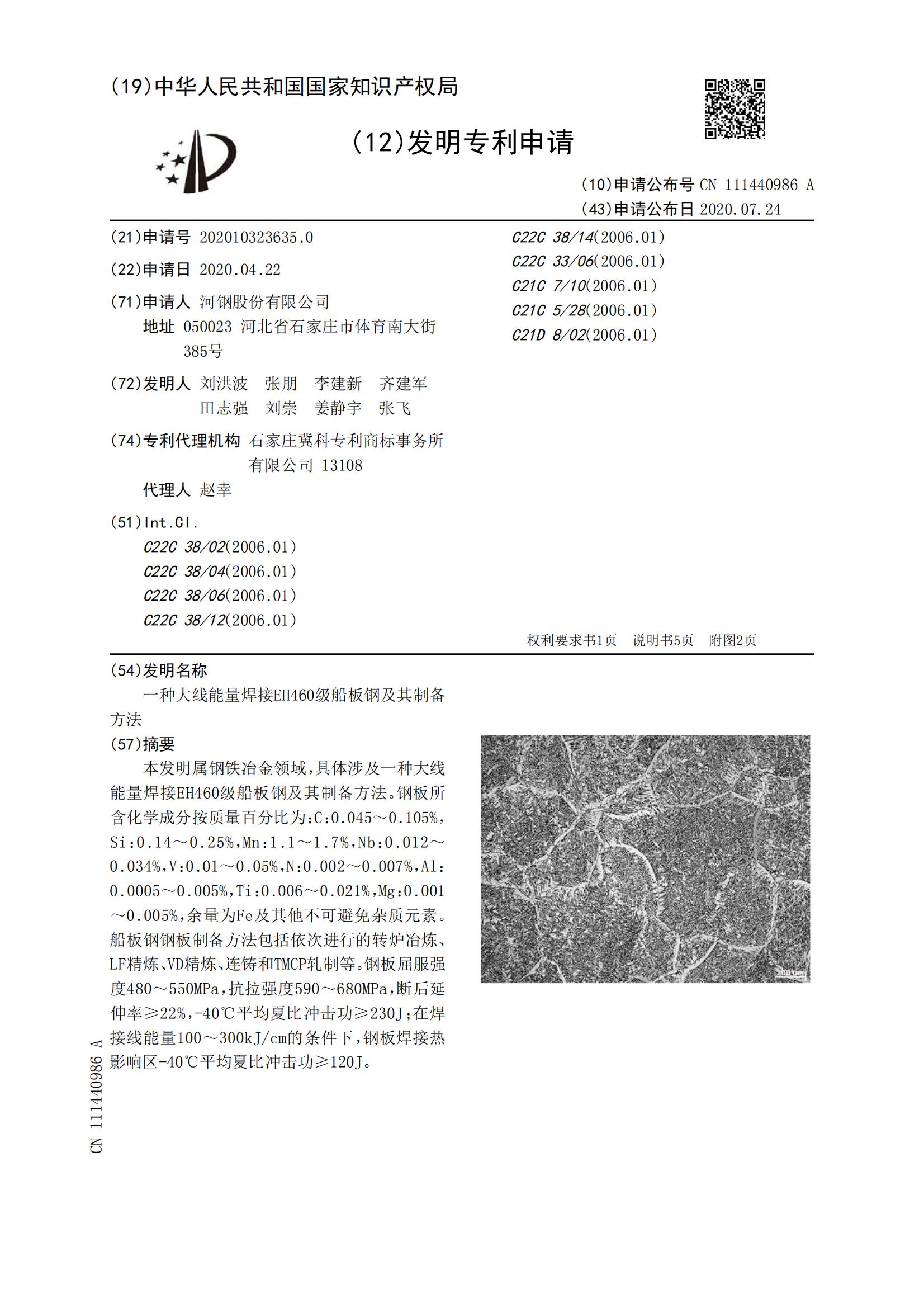

本发明属钢铁冶金领域,具体涉及一种大线能量焊接EH460级船板钢及其制备方法。钢板所含化学成分按质量百分比为:C:0.045~0.105%,Si:0.14~0.25%,Mn:1.1~1.7%,Nb:0.012~0.034%,V:0.01~0.05%,N:0.002~0.007%,Al:0.0005~0.005%,Ti:0.006~0.021%,Mg:0.001~0.005%,余量为Fe及其他不可避免杂质元素。船板钢钢板制备方法包括依次进行的转炉冶炼、LF精炼、VD精炼、连铸和TMCP轧制等。钢板屈服强度480~550MPa,抗拉强度590~680MPa,断后延伸率≥22%,‑40℃平均夏比冲击功≥230J;在焊接线能量100~300kJ/cm的条件下,钢板焊接热影响区‑40℃平均夏比冲击功≥120J。

The invention belongs to the field of ferrous metallurgy, and particularly relates to large-heat input welding EH460 stage ship plate steel and a preparing method thereof. A steel plate comprises chemical components including, by mass percent, 0.045 to 0.105% of C, 0.14 to 0.25% of Si, 1.1 to 1.7% of Mn, 0.012 to 0.034% of Nb, 0.01 to 0.05% of V, 0.002 to 0.007% of N, 0.0005 to 0.005% of Al, 0.006 to 0.021% of Ti, 0.001 to 0.005% of Mg, and the balance Fe and other inevitable impurities. A preparing method of the steel plate of the ship plate steel comprises converter smelting, LF refining,VD refining, continuous casting, TMCP rolling and the like which are carried out in sequence, the yield strength of the steel plate is 480 to 550 MPa, the tensile strength is 590 to 680 MPa, the specific elongation is larger than or equal to 22%, -40 ℃ average Charpy impact work is larger than or equal to 230 J, and under the condition that the welding linear energy is 100 to 300 kJ/cm, the steel plate welding heat influence area -40 ℃ average Charpy impact work is larger than or equal to 120J.