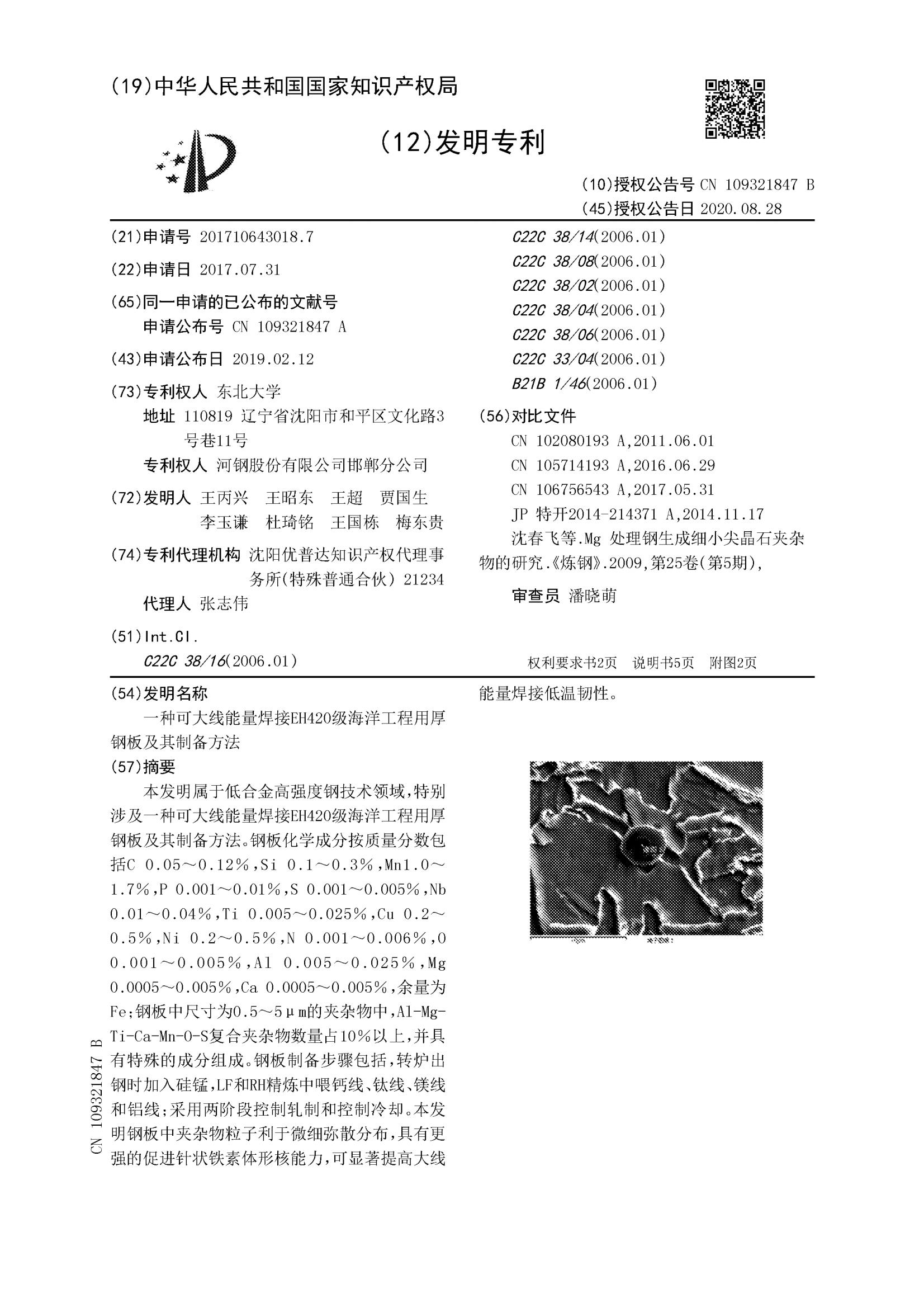

本发明属于低合金高强度钢技术领域,特别涉及一种可大线能量焊接EH420级海洋工程用厚钢板及其制备方法.钢板化学成分按质量分数包括C 0.05~0.12%,Si 0.1~0.3%,Mn1.0~1.7%,P 0.001~0.01%,S 0.001~0.005%,Nb 0.01~0.04%,Ti 0.005~0.025%,Cu 0.2~0.5%,Ni 0.2~0.5%,N 0.001~0.006%,O 0.001~0.005%,Al 0.005~0.025%,Mg 0.0005~0.005%,Ca 0.0005~0.005%,余量为Fe;钢板中尺寸为0.5~5μm的夹杂物中,AlMgTiCaMnOS复合夹杂物数量占10%以上,并具有特殊的成分组成.钢板制备步骤包括,转炉出钢时加入硅锰,LF和RH精炼中喂钙线,钛线,镁线和铝线;采用两阶段控制轧制和控制冷却。本发明钢板中夹杂物粒子利于微细弥散分布,具有更强的促进针状铁素体形核能力,可显著提高大线能量焊接低温韧性。

The invention belongs to the technical field of low-alloy high-strength steel, and particularly relates to a thick steel plate suitable for large heat input welding in EH420 grade marine engineering and a preparation method of the thick steel plate. The steel plate comprises the following chemical components of, by mass percentage, 0.05-0.12% of C, 0.1-0.3% of Si, 1.0-1.7% of Mn, 0.001-0.01% of P,0.001-0.005% of S, 0.01-0.04% of Nb, 0.005-0.025% of Ti, 0.2-0.5% of Cu, 0.2-0.5% of Ni, 0.001-0.006% of N, 0.001-0.005% of O, 0.005-0.025% of Al, 0.0005-0.005% of Mg, 0.0005-0.005% of Ca and the balance of Fe. Al-Mg-Ti-Ca-Mn-O-S composite inclusions account for more than 10% of inclusions with the sizes of 0.5-5 [mu]m in the steel plate and have special compositions. The steel plate is preparedaccording to the steps of adding silicon and manganese when steel is discharged from a converter, and feeding calcium wires, titanium wires, magnesium wires and aluminum wires during LF and RH refining; and adopting two-stage controlled rolling and controlled cooling. Particles of the inclusions in the steel plate are favorable for fine dispersion and distribution, have a better capability of promoting acicular ferrite nucleation, and can obviously improve low-temperature toughness of large heat input welding.