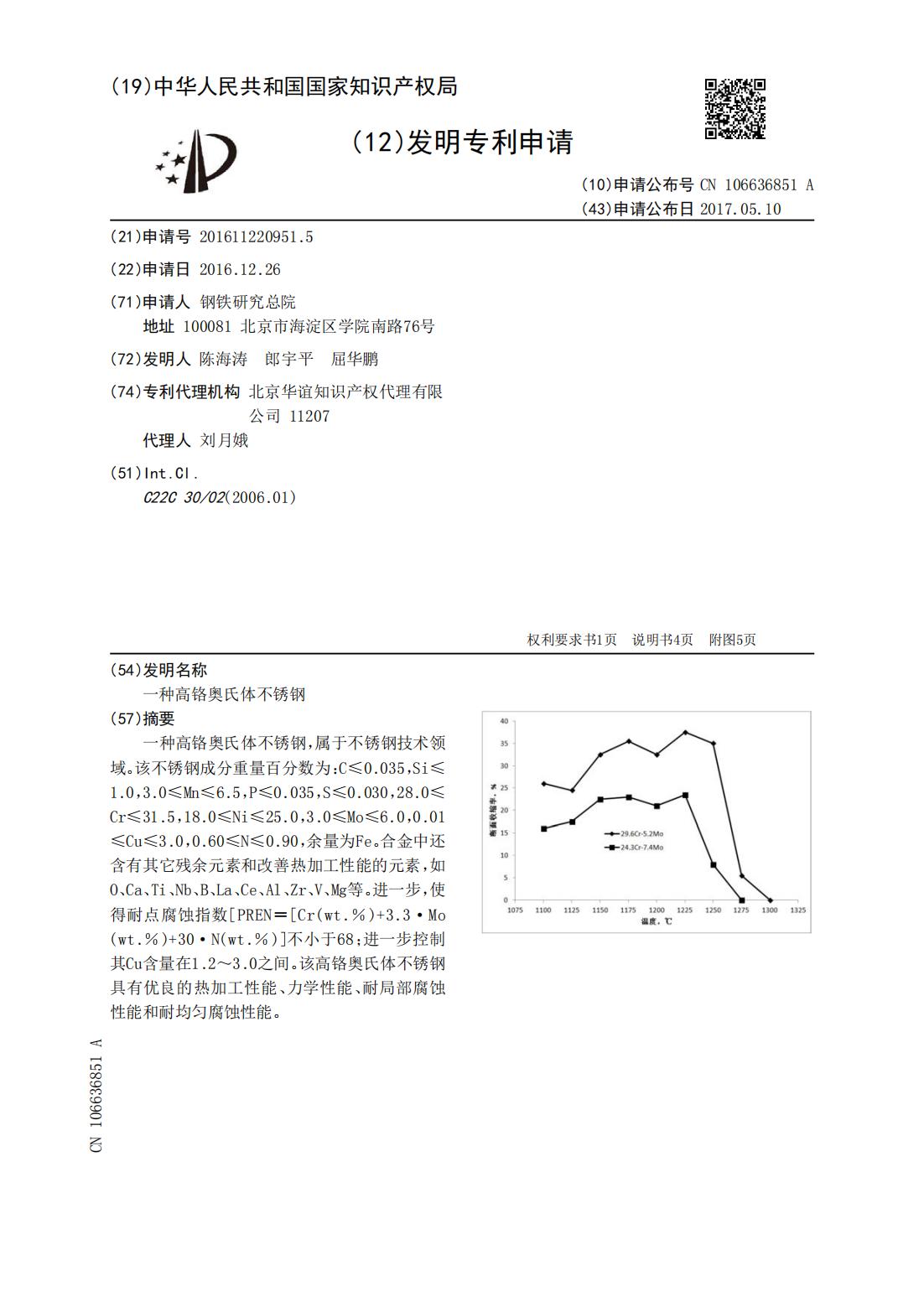

一种高铬奥氏体不锈钢,属于不锈钢技术领 域。该不锈钢成分重量百分数为:C≤0 .035,Si≤ 1 .0,3 .0≤Mn≤6 .5,P≤0 .035,S≤0 .030,28 .0≤ Cr≤31 .5,18 .0≤Ni≤25 .0,3 .0≤Mo≤6 .0,0 .01 ≤Cu≤3 .0,0 .60≤N≤0 .90,余量为Fe。合金中还 含有其它残余元素和改善热加工性能的元素,如 O、Ca、Ti、Nb、B、La、Ce、Al、Zr、V、Mg等。进一步,使 得耐点腐蚀指数[ PREN=[ Cr( wt .% )+3 .3·Mo ( wt .% )+30·N( wt .% )]不小于68;进一步控制 其Cu含量在1 .2~3 .0之间。该高铬奥氏体不锈钢 具有优良的热加工性能、力学性能、耐局部腐蚀 性能和耐均匀腐蚀性能。

A high chromium austenitic stainless steel, which belongs to the technical field of stainless steel. The weight percentage of the stainless steel composition is: C ≤ 0.035, Si ≤ 1.0, 3.0 ≤ Mn ≤ 6.5, P ≤ 0.035, s ≤ 0.030, 28.0 ≤ Cr ≤ 31.5, 18.0 ≤ Ni ≤ 25.0, 3.0 ≤ Mo ≤ 6.0, 0.01 ≤ Cu ≤ 3.0, 0.60 ≤ n ≤ 0.90, and the balance is Fe. The alloy also contains other residual elements and elements that improve hot working properties, such as O, CA, Ti, Nb, B, La, CE, Al, Zr, V, Mg, etc. Further, the pitting corrosion resistance index [PREN = [Cr (wt.%) + 3.3 · mo (wt.%) + 30 · n (wt.%)] is not less than 68, and the Cu content is further controlled between 1.2 and 3.0. The high chromium austenitic stainless steel has excellent hot working properties, mechanical properties, local corrosion resistance and uniform corrosion resistance.