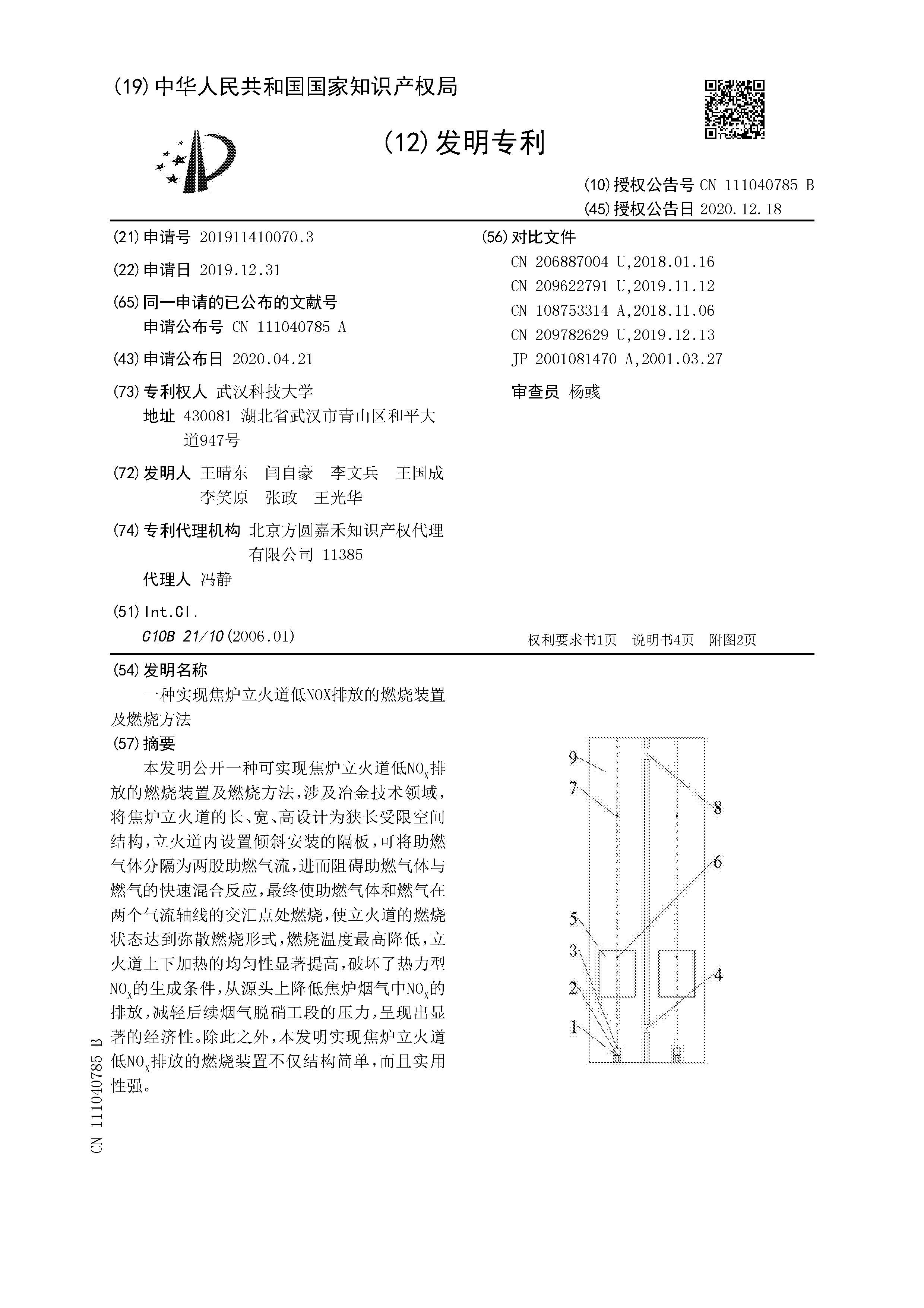

本发明公开一种可实现焦炉立火道低NOX排放的燃烧装置及燃烧方法,涉及冶金技术领域,将焦炉立火道的长、宽、高设计为狭长受限空间结构,立火道内设置倾斜安装的隔板,可将助燃气体分隔为两股助燃气流,进而阻碍助燃气体与燃气的快速混合反应,最终使助燃气体和燃气在两个气流轴线的交汇点处燃烧,使立火道的燃烧状态达到弥散燃烧形式,燃烧温度最高降低,立火道上下加热的均匀性显著提高,破坏了热力型NOX的生成条件,从源头上降低焦炉烟气中NOX的排放,减轻后续烟气脱硝工段的压力,呈现出显著的经济性。除此之外,本发明实现焦炉立火道低NOX排放的燃烧装置不仅结构简单,而且实用性强。

The invention discloses a combustion device and a combustion method that can realize low NOx emission from the coke oven vertical fire channel, which relates to the technical field of metallurgy. The length, width and height of the coke oven vertical fire channel are designed as a narrow and long confined space structure, and an inclined partition plate is arranged in the vertical fire channel, which can separate the combustion supporting gas into two combustion supporting gas streams, so as to hinder the rapid mixing reaction of combustion supporting gas and gas, Finally, the combustion supporting gas and fuel gas are burned at the intersection of the two gas flow axes, so that the combustion state of the vertical flue reaches the form of dispersion combustion, the maximum combustion temperature is reduced, the uniformity of heating up and down the vertical flue is significantly improved, the generation conditions of thermal NOx are destroyed, the emission of NOx in coke oven flue gas is reduced from the source, and the pressure of subsequent flue gas denitration section is reduced, It shows significant economy. In addition, the combustion device for realizing low NOx emission in the vertical fire path of the coke oven has simple structure and strong practicability.