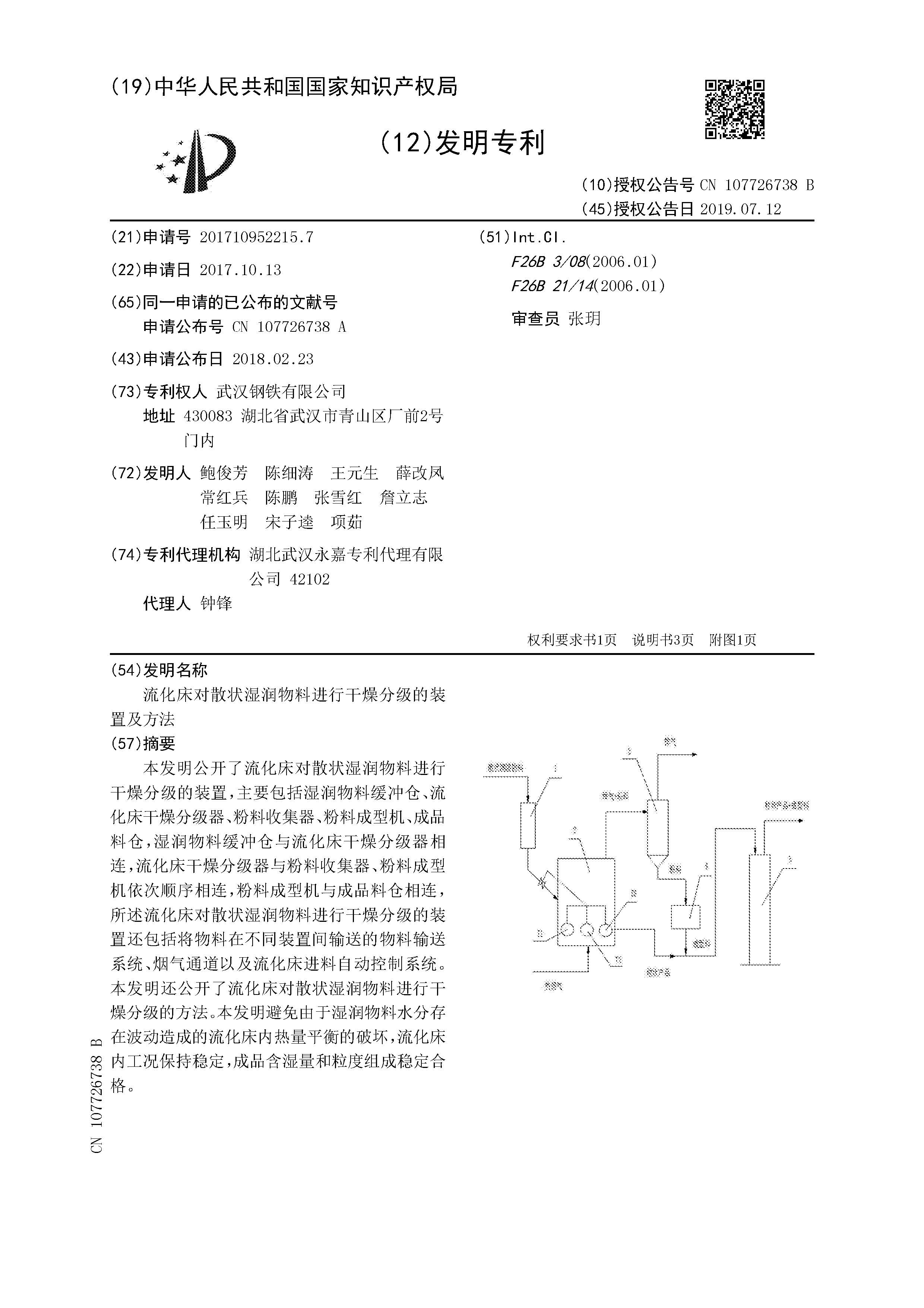

本发明公开了流化床对散状湿润物料进行干燥分级的装置,主要包括湿润物料缓冲仓、流化床干燥分级器、粉料收集器、粉料成型机、成品料仓,湿润物料缓冲仓与流化床干燥分级器相连,流化床干燥分级器与粉料收集器、粉料成型机依次顺序相连,粉料成型机与成品料仓相连,所述流化床对散状湿润物料进行干燥分级的装置还包括将物料在不同装置间输送的物料输送系统、烟气通道以及流化床进料自动控制系统。本发明还公开了流化床对散状湿润物料进行干燥分级的方法。本发明避免由于湿润物料水分存在波动造成的流化床内热量平衡的破坏,流化床内工况保持稳定,成品含湿量和粒度组成稳定合格。

The invention discloses a device for drying and grading bulk wet materials in a fluidized bed, which mainly comprises a wet material buffer bin, a fluidized bed drying classifier, a powder collector, a powder forming machine and a finished product bin. The wet material buffer bin is connected with the fluidized bed drying classifier, and the fluidized bed drying classifier is sequentially connected with the powder collector and the powder forming machine, The powder forming machine is connected with the finished product silo. The fluidized bed drying and grading device for bulk wet materials also includes a material conveying system for conveying materials between different devices, a flue gas channel and a fluidized bed feeding automatic control system. The invention also discloses a method for drying and grading bulk wet materials in a fluidized bed. The invention avoids the destruction of the heat balance in the fluidized bed caused by the fluctuation of the moisture of the wet material, the working condition in the fluidized bed remains stable, and the moisture content and particle size composition of the finished product are stable and qualified.