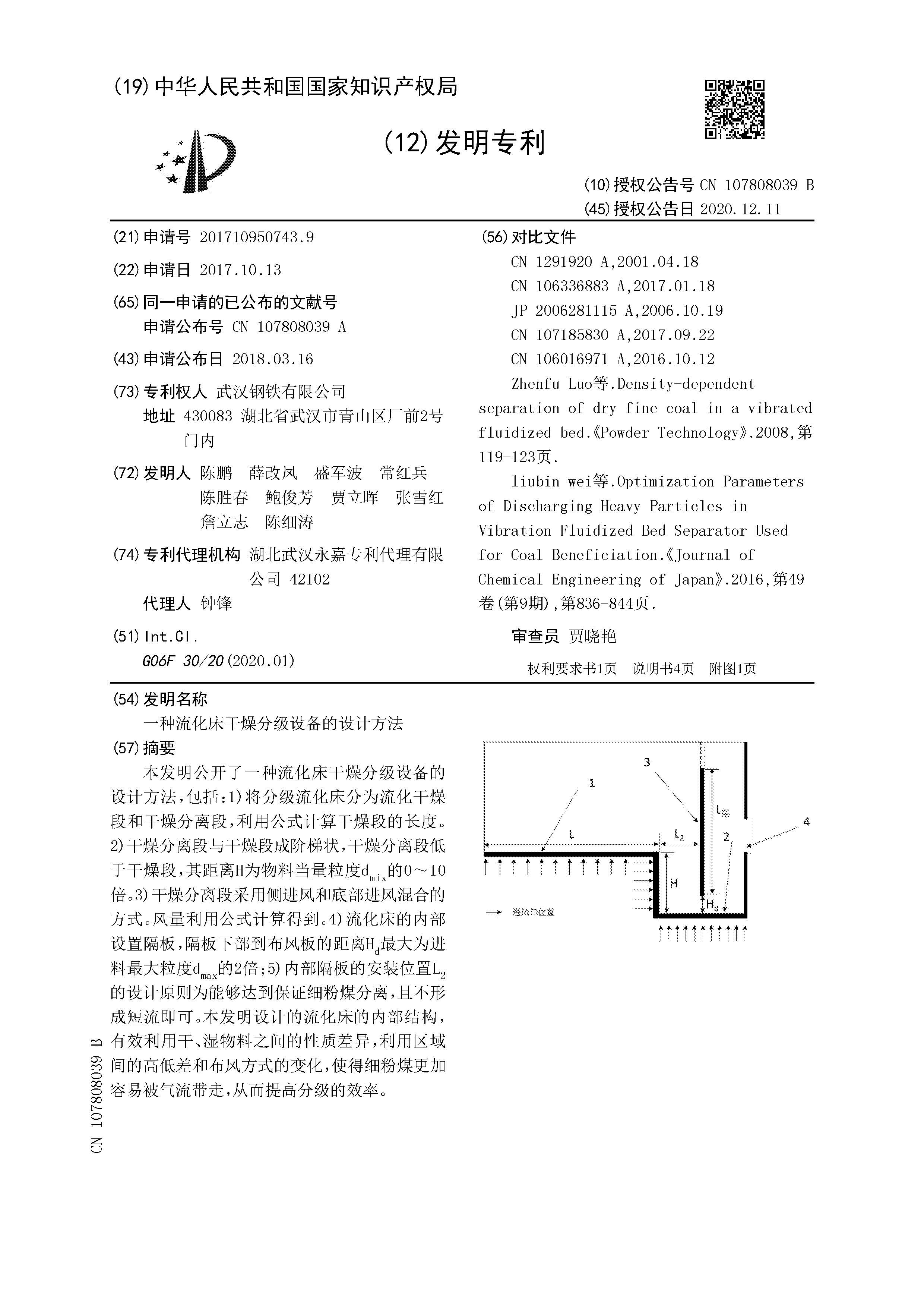

本发明公开了一种流化床干燥分级设备 设计方法,包括:1)将分级流化床分为流化干燥段和干燥分离段,利用公式计算干燥段的长度。 2)干燥分离段与干燥段成阶梯状,干燥分离段于干燥段,其距离H为物料当量粒度dmix的0~10倍。3)干燥分离段采用侧进风和底部进风混合的方式。风量利用公式计算得到。4)流化床的内部设置隔板,隔板下部到布风板的距离Hd最大为进料最大粒度dmax的2倍;5)内部隔板的安装位置L2的设计原则为能够达到保证细粉煤分离,且不形成短流即可。本发明设计的流化床的内部结构, 有效利用干、湿物料之间的性质差异,利用区域间的高低差和布风方式的变化,使得细粉煤更加容易被气流带走,从而提高分级的效率。

The invention discloses a design method of fluidized bed drying and classification equipment, which comprises: 1) dividing the graded fluidized bed into fluidization drying section and drying separation section, and using the formula to calculate the length of the drying section. 2) The drying separation section is stepped with the drying section. The drying separation section is located in the drying section, and its distance h is 0 ~ 10 times of the material equivalent particle size dmix. 3) The drying separation section adopts the mixing mode of side air inlet and bottom air inlet. The air volume is calculated by the formula. 4) A baffle is set inside the fluidized bed, and the maximum distance HD from the lower part of the baffle to the air distribution plate is 2 times of the maximum particle size Dmax of the feed; 5) The design principle of the installation position L2 of the internal diaphragm is to ensure the separation of fine pulverized coal without short flow. The internal structure of the fluidized bed designed by the invention effectively makes use of the property difference between dry and wet materials, the height difference between regions and the change of air distribution mode, so that the fine pulverized coal is easier to be taken away by the air flow, so as to improve the classification efficiency.