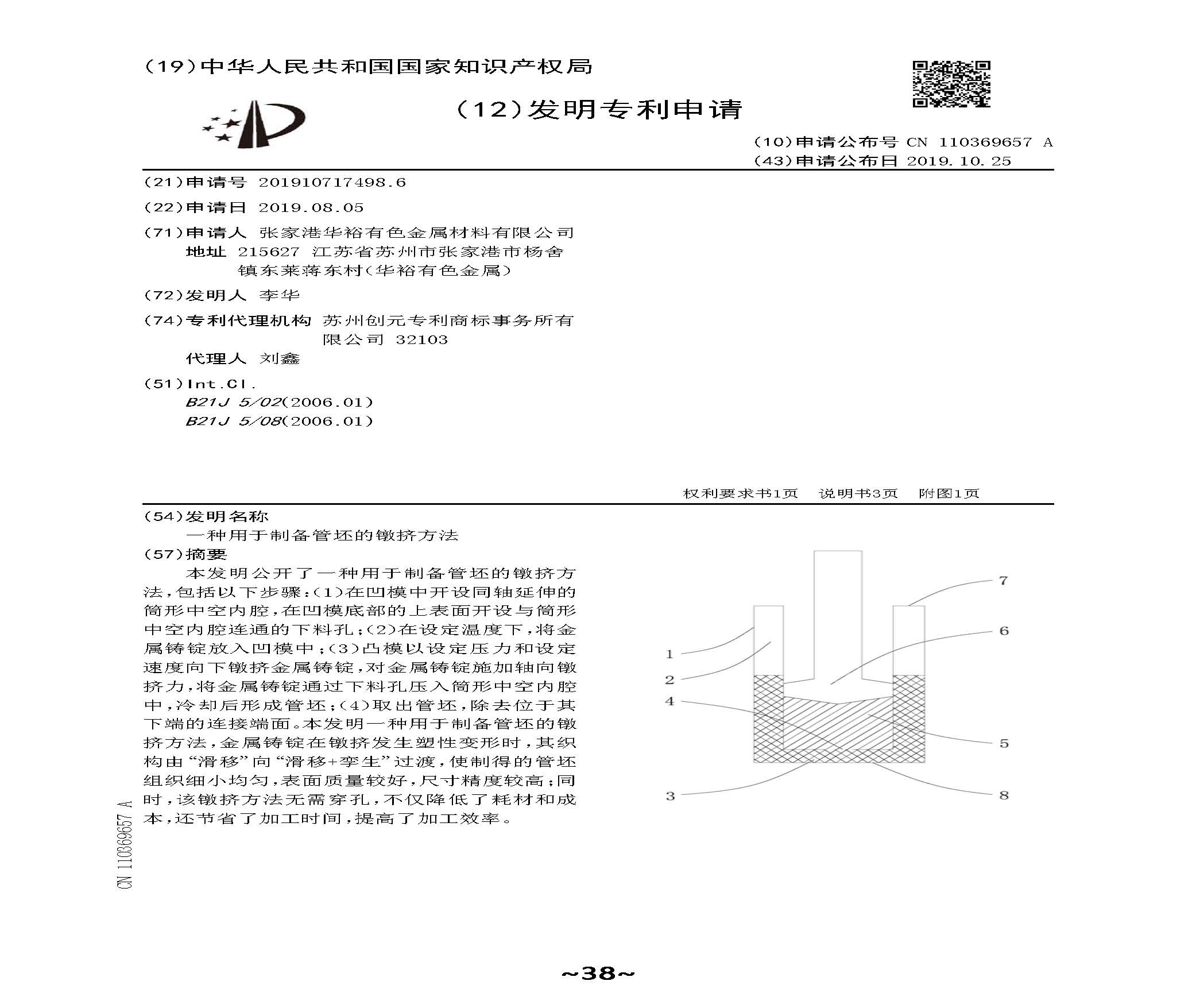

本发明公开了一种用于制备管坯的镦挤方法,包括以下步骤:(1)在凹模中开设同轴延伸的筒形中空内腔,在凹模底部的上表面开设与筒形中空内腔连通的下料孔;(2)在设定温度下,将金属铸锭放入凹模中;(3)凸模以设定压力和设定速度向下镦挤金属铸锭,对金属铸锭施加轴向镦挤力,将金属铸锭通过下料孔压入筒形中空内腔中,冷却后形成管坯;(4)取出管坯,除去位于其下端的连接端面。本发明一种用于制备管坯的镦挤方法,金属铸锭在镦挤发生塑性变形时,其织构由“滑移”向“滑移+孪生”过渡,使制得的管坯组织细小均匀,表面质量较好,尺寸精度较高;同时,该镦挤方法无需穿孔,不仅降低了耗材和成本,还节省了加工时间,提高了加工效率。

The invention discloses an upsetting extrusion method for preparing a pipe blank. The upsetting extrusion method comprises the following steps that (1) a cylindrical hollow inner cavity which extendscoaxially is formed in a female die, and a blanking hole communicating with the cylindrical hollow inner cavity is formed in the upper surface of the bottom of the female die; (2) a metal ingot is placed into the female die at a set temperature; (3) the metal ingot is upset and extruded downwards at a set pressure and a set speed by the female die, axial upsetting extrusion force is applied to themetal ingot, the metal ingot is pressed into the cylindrical hollow inner cavity through the blanking hole, and the pipe blank is formed after cooling; and (4) the pipe blank is taken out, and a connecting end face located at the lower end of the pipe blank is removed. According to the upsetting extrusion method for preparing the pipe blank, when the metal ingot is plastically deformed during upsetting extrusion, the texture of the metal ingot is transited from 'slippage' to 'slippage and twin', so that the prepared pipe blank is fine and uniform in structure, good in surface quality and highin size precision; and meanwhile, the upsetting extrusion method does not require perforation, so that the consumables and the cost are reduced, the machining time is saved, and the machining efficiency is improved.