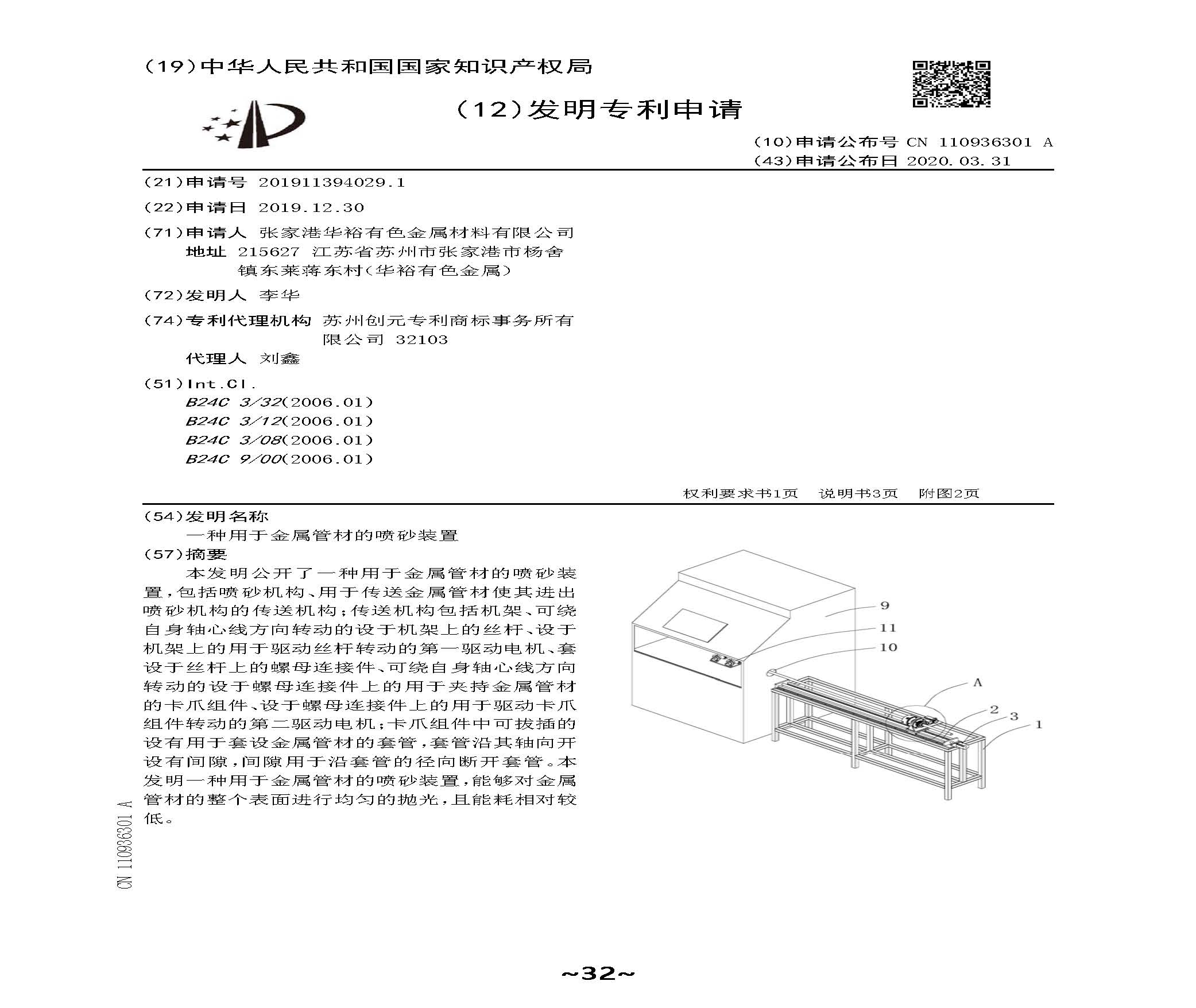

本发明公开了一种用于金属管材的喷砂装置,包括喷砂机构、用于传送金属管材使其进出喷砂机构的传送机构;传送机构包括机架、可绕自身轴心线方向转动的设于机架上的丝杆、设于机架上的用于驱动丝杆转动的第一驱动电机、套设于丝杆上的螺母连接件、可绕自身轴心线方向转动的设于螺母连接件上的用于夹持金属管材的卡爪组件、设于螺母连接件上的用于驱动卡爪组件转动的第二驱动电机;卡爪组件中可拔插的设有用于套设金属管材的套管,套管沿其轴向开设有间隙,间隙用于沿套管的径向断开套管。本发明一种用于金属管材的喷砂装置,能够对金属管材的整个表面进行均匀的抛光,且能耗相对较低。

The invention discloses a sand blasting device for a metal pipe. The device comprises a sand blasting mechanism and a conveying mechanism used for conveying the metal pipe to enter and exit from the sand blasting mechanism, wherein the conveying mechanism comprises a rack, a lead screw which is arranged on the rack and can rotate around the axis of the lead screw, a first driving motor which is arranged on the rack and used for driving the lead screw to rotate, a nut connecting piece arranged on the lead screw in a sleeving mode, a clamping jaw assembly which can rotate around the axis of theclamping jaw assembly, is arranged on the nut connecting piece and used for clamping a metal pipe, and a second driving motor which is arranged on the nut connecting piece and used for driving the clamping jaw assembly to rotate, wherein a sleeve used for being sleeved with the metal pipe is arranged in the clamping jaw assembly in a pluggable mode, a gap is formed in the sleeve in the axial direction of the sleeve, and the gap is used for disconnecting the sleeve in the radial direction of the sleeve. The device is advantaged in that the whole surface of the metal pipe can be uniformly polished, and energy consumption is relatively low.