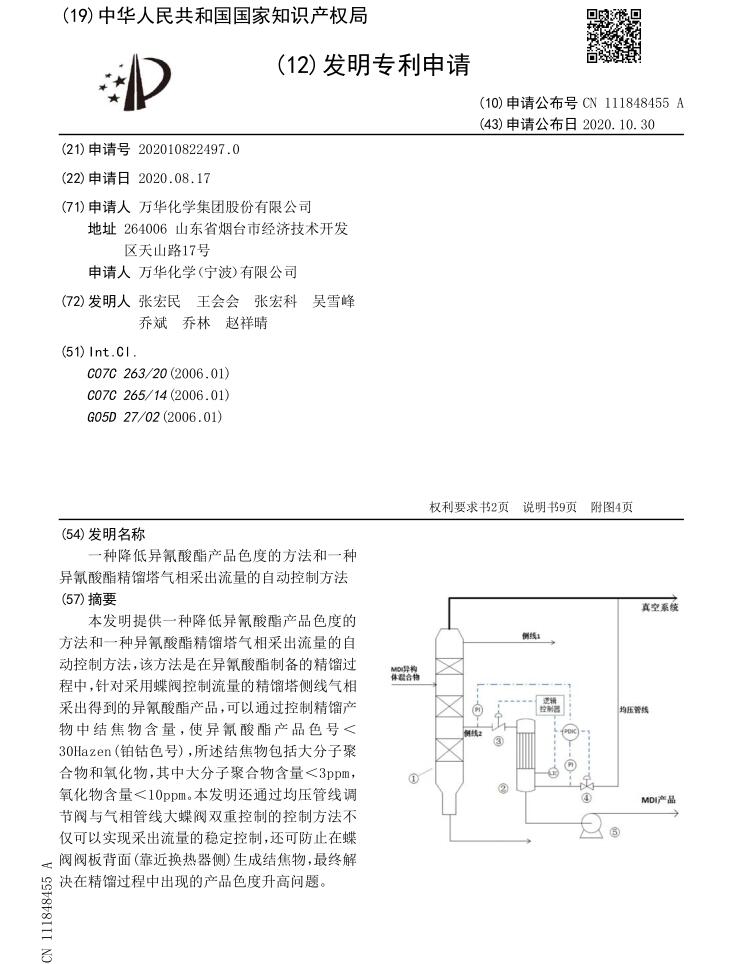

本发明提供一种降低异氰酸酯产品色度的方法和一种异氰酸酯精馏塔气相采出流量的自动控制方法,该方法是在异氰酸酯制备的精馏过程中,针对采用蝶阀控制流量的精馏塔侧线气相采出得到的异氰酸酯产品,可以通过控制精馏产物中结焦物含量 ,使异氰酸酯产品色号<30Hazen(铂钴色号),所述结焦物包括大分子聚合物和氧化物,其中大分子聚合物含量<3ppm,氧化物含量<10ppm。本发明还通过均压管线调节阀与气相管线大蝶阀双重控制的控制方法不仅可以实现采出流量的稳定控制,还可防止在蝶阀阀板背面(靠近换热器侧)生成结焦物,最终解决在精馏过程中出现的产品色度升高问题。

The invention provides a method for reducing the chromaticity of an isocyanate product and an automatic control method for the gas-phase extraction flow of an isocyanate rectifying tower. The method is used in a rectification process of isocyanate preparation. Directed at an isocyanate product obtained by rectifying tower side gas-phase extraction adopting a butterfly valve to control flow, the color number of the isocyanate product can be less than 30 Hazen (platinum-cobalt color number) by controlling the content of a coking material in the rectification product, the coking material comprises a macromolecular polymer and an oxide, the content of the macromolecular polymer is less than 3ppm, and the content of the oxide is less than 10ppm. By means of the control method of dual control ofa pressure equalizing pipeline adjusting valve and a gas phase pipeline large butterfly valve, stable control over the extracted flow can be achieved, coking substances can be prevented from being generated on the back face (close to a heat exchanger side) of the butterfly valve plate, and finally the problem that the product chromaticity rises in the rectification process is solved.