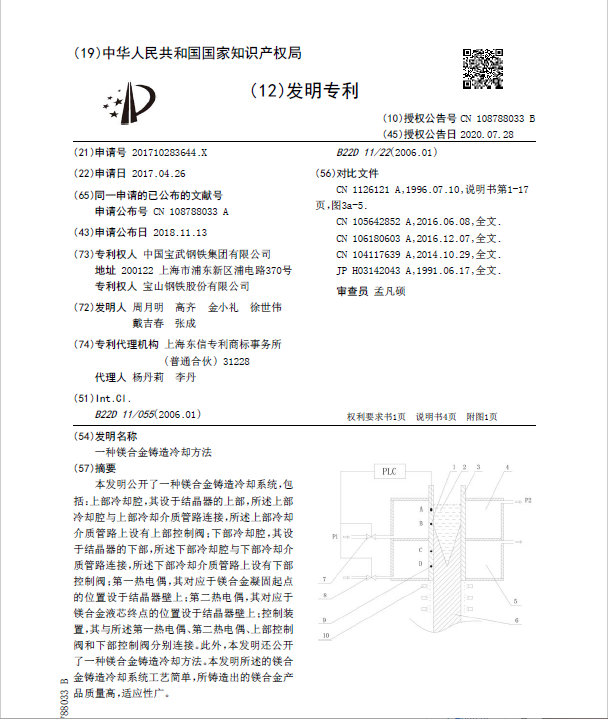

本发明公开了一种镁合金铸造冷却系统,包括:上部冷却腔,其设于结晶器的上部,所述上部冷却腔与上部冷却介质管路连接,所述上部冷却介质管路上设有上部控制阀;下部冷却腔,其设于结晶器的下部,所述下部冷却腔与下部冷却介质管路连接,所述下部冷却介质管路上设有下部控制阀;第一热电偶,其对应于镁合金凝固起点的位置设于结晶器壁上;第二热电偶,其对应于镁合金液芯终点的位置设于结晶器壁上;控制装置,其与所述第一热电偶、第二热电偶、上部控制阀和下部控制阀分别连接。此外,本发明还公开了一种镁合金铸造冷却方法。本发明所述的镁合金铸造冷却系统工艺简单,所铸造出的镁合金产品质量高,适应性广。

The invention discloses a magnesium alloy casting cooling system, which comprises: an upper cooling chamber, which is arranged at the upper part of the mold, the upper cooling chamber is connected with the upper cooling medium pipeline, and the upper cooling medium pipeline is provided with an upper control valve; The lower cooling chamber is arranged at the lower part of the mold, the lower cooling chamber is connected with the lower cooling medium pipeline, and the lower cooling medium pipeline is provided with a lower control valve; A first thermocouple whose position corresponding to the solidification starting point of magnesium alloy is arranged on the mold wall; A second thermocouple corresponding to the end point of the magnesium alloy liquid core is arranged on the mold wall; The control device is respectively connected with the first thermocouple, the second thermocouple, the upper control valve and the lower control valve. In addition, the invention also discloses a magnesium alloy casting cooling method. The magnesium alloy casting cooling system has the advantages of simple process, high quality and wide adaptability.