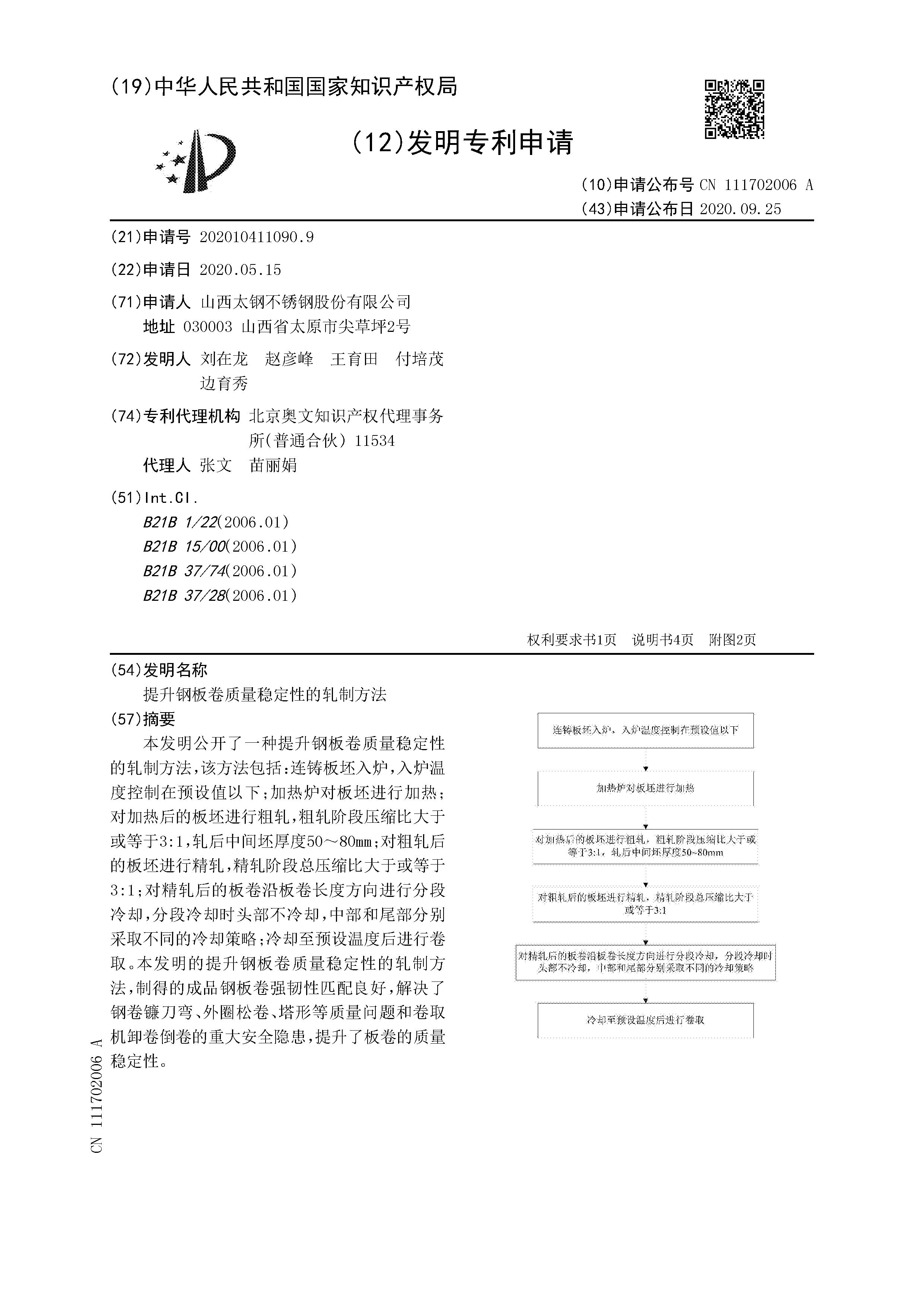

本发明公开了一种提升钢板卷质量稳定性的轧制方法,该方法包括:连铸板坯入炉,入炉温度控制在预设值以下;加热炉对板坯进行加热;对加热后的板坯进行粗轧,粗轧阶段压缩比大于或等于3:1,轧后中间坯厚度50~80mm;对粗轧后的板坯进行精轧,精轧阶段总压缩比大于或等于3:1;对精轧后的板卷沿板卷长度方向进行分段冷却,分段冷却时头部不冷却,中部和尾部分别采取不同的冷却策略;冷却至预设温度后进行卷取。本发明的提升钢板卷质量稳定性的轧制方法,制得的成品钢板卷强韧性匹配良好,解决了钢卷镰刀弯、外圈松卷、塔形等质量问题和卷取机卸卷倒卷的重大安全隐患,提升了板卷的质量稳定性。

The invention discloses a rolling method for improving the quality stability of coils. The method includes: entering a continuous casting slab into a furnace, and controlling the entering temperature below a preset value; a heating furnace heating the slab; and heating the slab after heating. The slab is rough-rolled, the compression ratio in the rough-rolling stage is greater than or equal to 3:1, and the thickness of the intermediate slab after rolling is 50-80mm; the rough-rolled slab is subjected to finishing rolling, and the total compression ratio in the finishing-rolling stage is greater than or equal to 3:1 ; The finished coil is cooled in sections along the length of the coil. The head is not cooled during the section cooling, and different cooling strategies are adopted for the middle and tail parts; coiling is performed after cooling to a preset temperature. The rolling method for improving the quality and stability of steel coils of the present invention has a good match in strength and toughness of the prepared steel coils, and solves the quality problems of steel coils with sickle bends, loose coils of outer rings, tower shapes, etc., and coil unloading and rewinding of coilers The major potential safety hazards have improved the quality and stability of the coil.