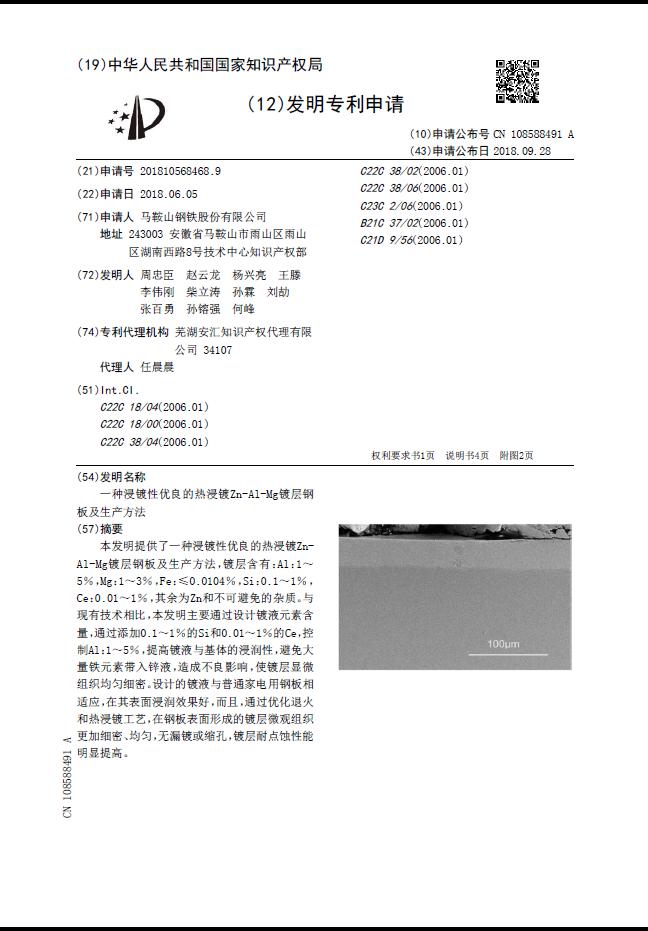

本发明提供了一种浸镀性优良的热浸镀Zn-Al-Mg镀层钢板及生产方法,镀层含有:Al:1%~5%,Mg:1%~3%,Fe:≤0 .0104%,Si:0 .1%~1%,Ce:0 .01%~1%,其余为Zn和不可避免的杂质。与现有技术相比,本发明主要通过设计镀液元素含量,通过添加0 .1%~1%的Si和0 .01%~1%的Ce,控制Al:1%~5%,提高镀液与基体的浸润性,避免大量铁元素带入锌液,造成不良影响,使镀层显微组织均匀细密。设计的镀液与普通家电用钢板相适应,在其表面浸润效果好,而且,通过优化退火和热浸镀工艺,在钢板表面形成的镀层微观组织更加细密、均匀,无漏镀或缩孔,镀层耐点蚀性能明显提高。

The invention provides a hot-dipping Zn-Al-Mg coating steel plate with an excellent dip plating performance, and a production method.A coating contains 1%~5% Al, 1%~3% Mg, less than or equal to 0.0104%Fe, 0.1%~1% Si, 0.1%~1% Ce, and the balance Zn and inevitable impurities. Compared with the prior art, according to the hot-dipping Zn-Al-Mg coating steel plate with the excellent dip plating performance, and the production method provided by the invention, through designing the plating solution element content, adding 0.1%~1%Si and 0.01%~1%Ce, and controlling Al to be 1%~5%, the infiltrating performance of a plating solution and a substrate is improved, and a large number of iron elements are prevented from being brought into zinc liquid so as to cause an adverse effect, so that the coating is uniform and fine in microstructure. The designed plating solution adapts to a steel plate for a common household appliance and has a good infiltrating effect on the surface of the steel plate; and in addition, through optimizing annealing and hot-dipping processes, the coating formed on the surface of the steel plate is fine and uniform in microstructure without skip plating or shrinking and is remarkably improved in pitting corrosion resistance.