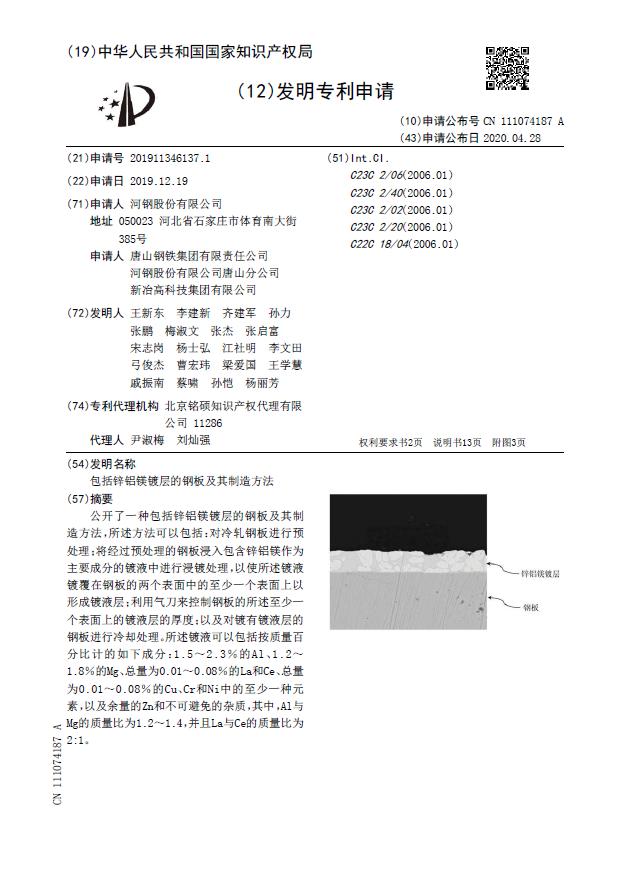

公开了一种包括锌铝镁镀层的钢板及其制造方法,所述方法可以包括:对冷轧钢板进行预处理;将经过预处理的钢板浸入包含锌铝镁作为主要成分的镀液中进行浸镀处理,以使所述镀液镀覆在钢板的两个表面中的至少一个表面上以形成镀液层;利用气刀来控制钢板的所述至少一个表面上的镀液层的厚度;以及对镀有镀液层的钢板进行冷却处理。所述镀液可以包括按质量百分比计的如下成分:1 .5~2 .3%的Al、1 .2~1 .8%的Mg、总量为0 .01~0 .08%的La和Ce、总量为0 .01~0 .08%的Cu、Cr和Ni中的至少一种元素,以及余量的Zn和不可避免的杂质,其中,Al与Mg的质量比为1 .2~1 .4,并且La与Ce的质量比为2:1。

The invention discloses a steel plate including a zinc-aluminum-magnesium coating and a manufacturing method of the steel plate. The method can include the steps that the cold-rolled steel plate is pretreated; the pre-treated steel plate is immersed into a plating solution containing zinc, aluminum and magnesium as main components for immersion plating treatment, so that at least one of the two surfaces of the steel plate is plated with the plating solution to form a plating solution layer; the thickness of the plating solution layer on at least one surface of the steel plate is controlled through an air knife; and the steel plate plated with the plating solution layer is cooled. The plating solution can be prepared from the following components in percentage by mass: at least one elementof 1.5-2.3% of Al, 1.2-1.8% of Mg, 0.01-0.08% in total of La and Ce, and 0.01-0.08% in total of Cu, Cr and Ni, and the balance of Zn and inevitable impurities, wherein the mass ratio of Al to Mg is 1.2 to 1.4, and the mass ratio of La to Ce is 2:1.