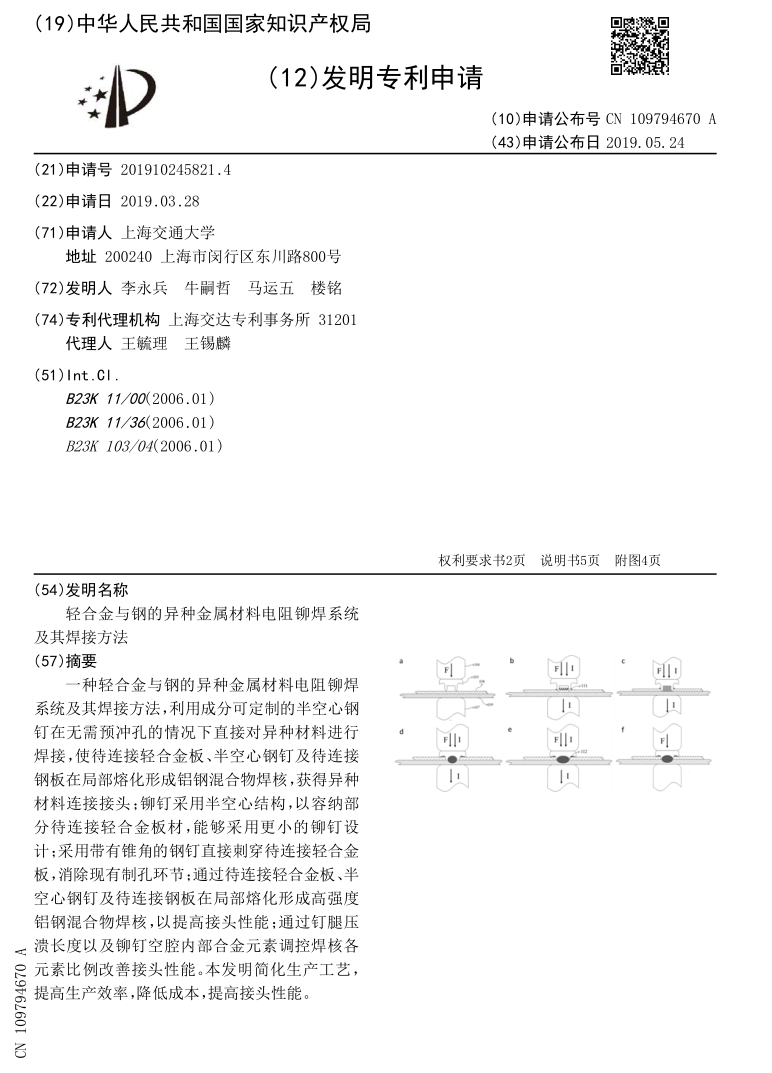

一种轻合金与钢的异种金属材料电阻铆焊系统及其焊接方法,利用成分可定制的半空心钢钉在无需预冲孔的情况下直接对异种材料进行焊接,使待连接轻合金板、半空心钢钉及待连接钢板在局部熔化形成铝钢混合物焊核,获得异种材料连接接头;铆钉采用半空心结构,以容纳部分待连接轻合金板材,能够采用更小的铆钉设计;采用带有锥角的钢钉直接刺穿待连接轻合金板,消除现有制孔环节;通过待连接轻合金板、半空心钢钉及待连接钢板在局部熔化形成高强度铝钢混合物焊核,以提高接头性能;通过钉腿压溃长度以及铆钉空腔内部合金元素调控焊核各元素比例改善接头性能。本发明简化生产工艺,提高生产效率,降低成本,提高接头性能。

The invention relates to a resistance riveting welding system for dissimilar metal materials of light alloy and steel and a welding method thereof. The dissimilar materials are directly welded without pre punching by using a semi hollow steel nail with customizable composition, so that the light alloy plate to be connected, the semi hollow steel nail and the steel plate to be connected are locally melted to form an aluminum steel mixture welding core, and the dissimilar material connection joint is obtained; The rivet adopts semi hollow structure to accommodate some light alloy plates to be connected, and smaller rivet design can be adopted; The steel nail with cone angle is used to directly pierce the light alloy plate to be connected to eliminate the existing hole making link; High strength aluminum steel mixture nugget is formed by local melting of light alloy plate to be connected, semi hollow steel nail and steel plate to be connected, so as to improve the performance of the joint; The performance of the joint was improved by adjusting the ratio of elements in the nugget through the crushing length of the nail leg and the alloy elements in the rivet cavity. The invention simplifies the production process, improves the production efficiency, reduces the cost and improves the joint performance.