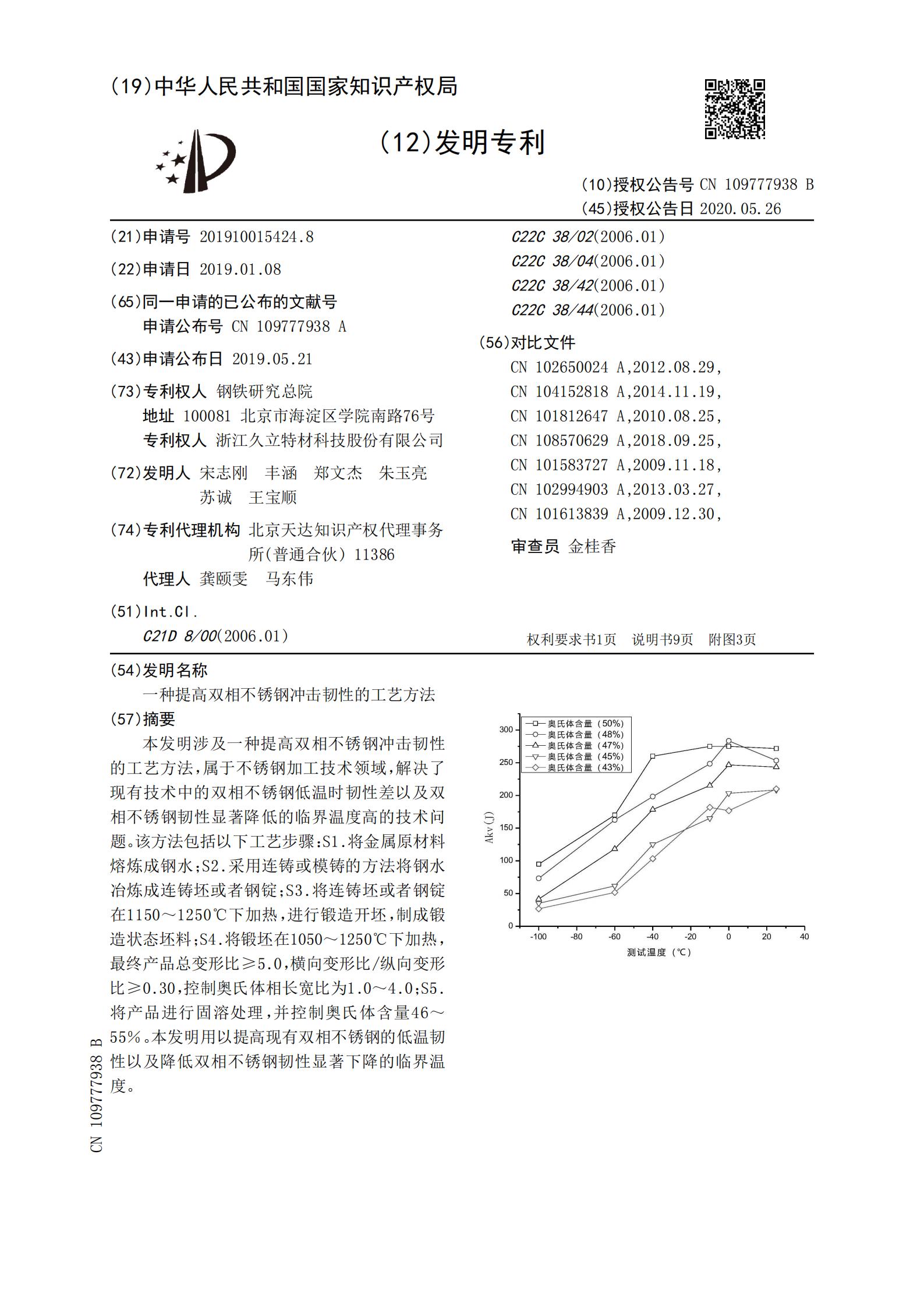

本发明涉及一种提高双相不锈钢冲击韧性的工艺方法,属于不锈钢加工技术领域,解决了现有技术中的双相不锈钢低温时韧性差以及双相不锈钢韧性显著降低的临界温度高的技术问题。该方法包括以下工艺步骤:S1 .将金属原材料熔炼成钢水;S2 .采用连铸或模铸的方法将钢水冶炼成连铸坯或者钢锭;S3 .将连铸坯或者钢锭在1150~1250℃下加热,进行锻造开坯,制成锻造状态坯料;S4 .将锻坯在1050~1250℃下加热, 最终产品总变形比≥5 .0,横向变形比/纵向变形 比≥0 .30,控制奥氏体相长宽比为1 .0~4 .0;S5 . 将产品进行固溶处理,并控制奥氏体含量46~ 55%。本发明用以提高现有双相不锈钢的低温韧性以及降低双相不锈钢韧性显著下降的临界温度。

The invention relates to a process method for improving the impact toughness of duplex stainless steel, which belongs to the technical field of stainless steel processing, and solves the technical problems of poor toughness of duplex stainless steel at low temperature and high critical temperature at which the toughness of duplex stainless steel is significantly reduced in the prior art. The method includes the following process steps: S1. Melting metal raw materials into molten steel; S2. Using continuous casting or die casting to smelt molten steel into continuous casting billets or steel ingots; S3. Putting the continuous casting billets or steel ingots at 1150~1250°C Heating, forging and billeting to make billet in forged state; S4. Heat the forging billet at 1050~1250℃, the final product total deformation ratio ≥ 5.0, transverse deformation ratio/longitudinal deformation ratio ≥ 0.30, control Austria The aspect ratio of the austenite phase is 1.0 to 4.0; S5. The product is solid solution treated and the austenite content is controlled at 46 to 55%. The invention is used to improve the low-temperature toughness of the existing duplex stainless steel and reduce the critical temperature at which the toughness of the duplex stainless steel significantly decreases.