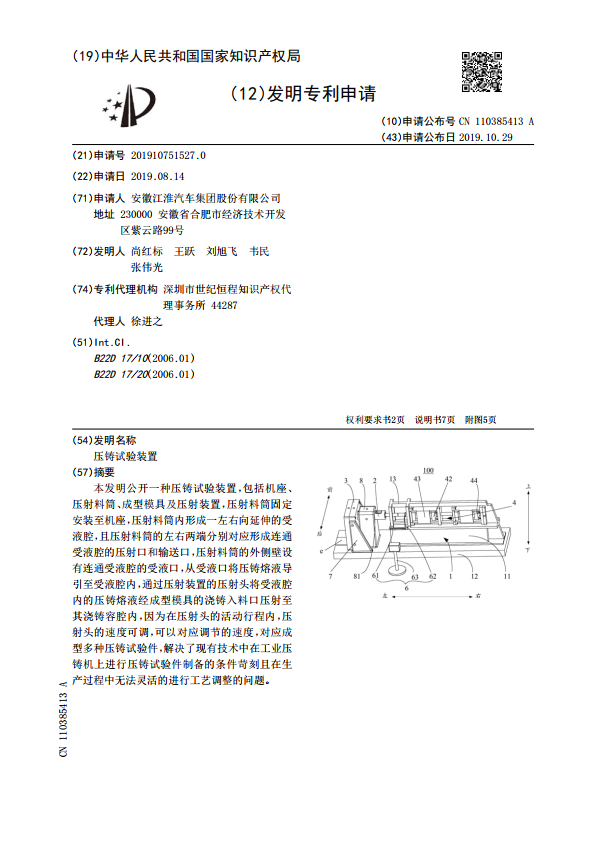

本发明公开一种压铸试验装置,包括机座、压射料筒、成型模具及压射装置,压射料筒固定安装至机座,压射料筒内形成一左右向延伸的受液腔,且压射料筒的左右两端分别对应形成连通受液腔的压射口和输送口,压射料筒的外侧壁设有连通受液腔的受液口,从受液口将压铸熔液导引至受液腔内,通过压射装置的压射头将受液腔内的压铸熔液经成型模具的浇铸入料口压射至其浇铸容腔内,因为在压射头的活动行程内,压射头的速度可调,可以对应调节的速度,对应成型多种压铸试验件,解决了现有技术中在工业压铸机上进行压铸试验件制备的条件苛刻且在生产过程中无法灵活的进行工艺调整的问题。

The invention discloses a die-casting test device, which comprises a machine base, an injection barrel, a forming mold and an injection device. The injection barrel is fixedly installed on the machine base, and a liquid receiving cavity extending from left to right is formed in the injection barrel. In addition, the left and right ends of the injection barrel respectively form an injection port and a delivery port communicating with the liquid receiving cavity. The outer side wall of the injection barrel is provided with a liquid receiving port communicating with the liquid receiving cavity. Guide into the liquid receiving cavity, the die-casting melt in the liquid receiving cavity is injected into the casting cavity through the casting inlet of the molding die through the injection head of the injection device, because the movement stroke of the injection head Inside, the speed of the injection head can be adjusted, corresponding to the adjusted speed, corresponding to the formation of a variety of die-casting test pieces, which solves the problem of the harsh conditions for the preparation of die-casting test pieces on the industrial die-casting machine in the prior art and the inflexibility in the production process. The problem of making process adjustments.