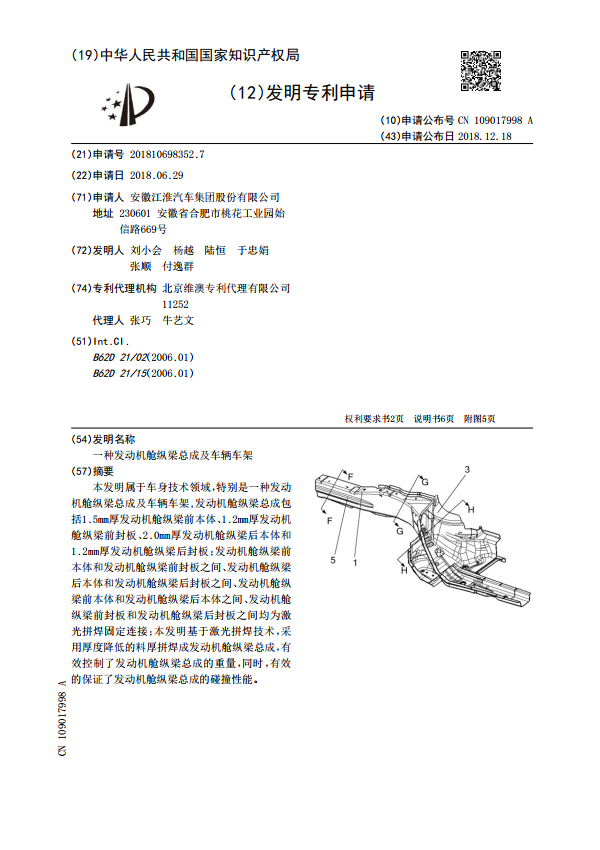

本发明属于车身技术领域,特别是一种发动机舱纵梁总成及车辆车架 ,发动机舱纵梁总成包括1 .5mm厚发动机舱纵梁前本体、1 .2mm厚发动机舱纵梁前封板、2 .0mm厚发动机舱纵梁后本体和1 .2mm厚发动机舱纵梁后封板;发动机舱纵梁前本体和发动机舱纵梁前封板之间、发动机舱纵梁后本体和发动机舱纵梁后封板之间、发动机舱纵梁前本体和发动机舱纵梁后本体之间、发动机舱纵梁前封板和发动机舱纵梁后封板之间均为激光拼焊固定连接;本发明基于激光拼焊技术,采用厚度降低的料厚拼焊成发动机舱纵梁总成,有效控制了发动机舱纵梁总成的重量,同时,有效的保证了发动机舱纵梁总成的碰撞性能。

The invention belongs to the technical field of vehicle bodies, in particular to an engine compartment longitudinal beam assembly and a vehicle frame. The engine compartment longitudinal beam assembly includes a 1.5mm thick engine compartment longitudinal beam front body and a 1.2mm thick engine compartment longitudinal beam front seal Plate, 2.0mm thick engine compartment longitudinal beam rear body and 1.2mm thick engine compartment longitudinal beam rear sealing plate; between engine compartment longitudinal beam front body and engine compartment longitudinal beam front sealing plate, engine compartment longitudinal beam rear body and engine Laser tailored welding is used between the rear sealing plates of the longitudinal beams of the cabin, the front body of the longitudinal beams of the engine compartment and the rear body of the longitudinal beams of the engine compartment, and the front sealing plates of the longitudinal beams of the engine compartment and the rear sealing plates of the longitudinal beams of the engine compartment. The invention is based on laser tailor welding technology, adopts tailor-welded material with reduced thickness to form the engine compartment longitudinal beam assembly, which effectively controls the weight of the engine compartment longitudinal beam assembly, and at the same time, effectively ensures the collision of the engine compartment longitudinal beam assembly performance.