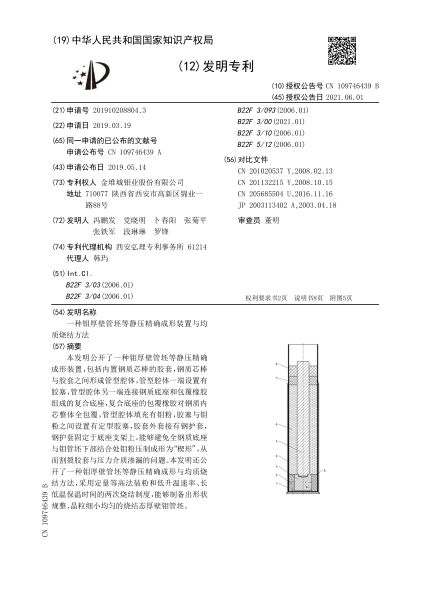

一种钼厚壁管坯等静压精确成形装置,包括内置钢质芯棒的胶套,钢质芯棒与胶套之间形成管型腔体,管型腔体一端设置有胶塞,管型腔体另一端连接钢质底座和包覆橡胶组成的复合底座,复合底座的包覆橡胶对钢质内芯整体全包覆,管型腔体填充有钼粉,胶塞与钼粉之间设置有定型胶塞,胶套外套接有钢护套,钢护套固定于底座支架上。能够避免全钢质底座与钼管坯下部结合处钼粉压制成形为“楔形”,从而割裂胶套与压力介质渗漏的问题。本发明还公开了一种钼厚壁管坯等静压精确成形与均质烧结方法,采用定量等高法装粉和低升温速率、长低温保温时间的两次烧结制度,能够制备出形状规整、晶粒细小均匀的烧结态厚壁钼管坯。

A precise isostatic pressing forming device for molybdenum thick-walled tube blanks includes a rubber sleeve with a built-in steel core rod. A tube-shaped cavity is formed between the steel core rod and the rubber sleeve. One end of the tube-shaped cavity is provided with a rubber plug,The other end of the cavity is connected to a composite base composed of a steel base and a covered rubber. The covering rubber of the composite base fully covers the steel inner core. The tube cavity is filled with molybdenum powder, between the rubber plug and the molybdenum powder.A shaped rubber plug is provided, and a steel sheath is connected to the outer sleeve of the rubber sleeve, and the steel sheath is fixed on the base bracket.It can avoid the problem of molybdenum powder being pressed into a "wedge shape" at the junction of the all-steel base and the lower part of the molybdenum tube billet, thereby splitting the rubber sleeve and leaking the pressure medium.The invention also discloses a method for precise isostatic pressing and homogeneous sintering of molybdenum thick-walled tube blanks, which adopts the two sintering system of quantitative equal height method, low heating rate and long low temperature holding time, and can prepare regular shapes., Sintered thick-walled molybdenum tube blank with fine and uniform grains.