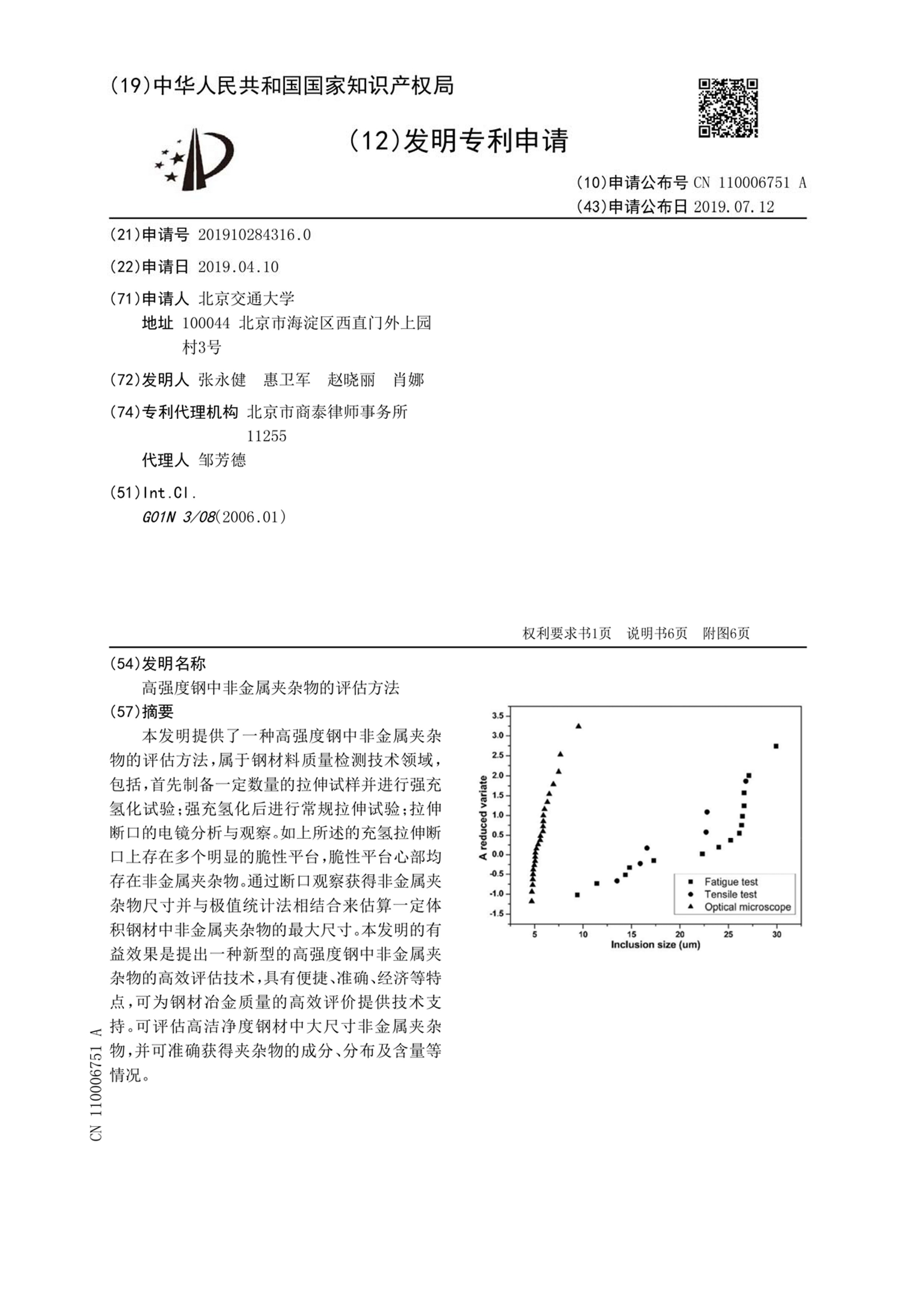

本发明提供了一种高强度钢中非金属夹杂物的评估方法,属于钢材料质量检测技术领域,包括,首先制备一定数量的拉伸试样并进行强充氢化试验;强充氢化后进行常规拉伸试验;拉伸断口的电镜分析与观察。如上所述的充氢拉伸断口上存在多个明显的脆性平台,脆性平台心部均存在非金属夹杂物。通过断口观察获得非金属夹杂物尺寸并与极值统计法相结合来估算一定体积钢材中非金属夹杂物的最大尺寸。本发明的有益效果是提出一种新型的高强度钢中非金属夹杂物的高效评估技术,具有便捷、准确、经济等特点,可为钢材冶金质量的高效评价提供技术支持。可评估高洁净度钢材中大尺寸非金属夹杂物,并可准确获得夹杂物的成分、分布及含量等情况。

The invention provides an evaluation method for non-metallic inclusions in high strength steel, which belongs to the technical field of steel material quality testing. Conventional tensile test was carried out after strong hydrogenation. Electron microscope analysis and observation of tensile fracture. There are many obvious brittle platforms on the hydrogen-filled tensile fracture mentioned above, and non-metallic inclusions exist in the core of the brittle platform. The maximum size of non-metallic inclusion in a certain volume steel can be estimated by using the method of extreme statistics. The beneficial effect of the invention is to propose a new efficient evaluation technology for non-metallic inclusions in high strength steel, which is convenient, accurate and economical, and can provide technical support for efficient evaluation of metallurgical quality of steel. It can be used to evaluate large size non-metallic inclusions in high clean steel, and accurately obtain the composition, distribution and content of inclusions.