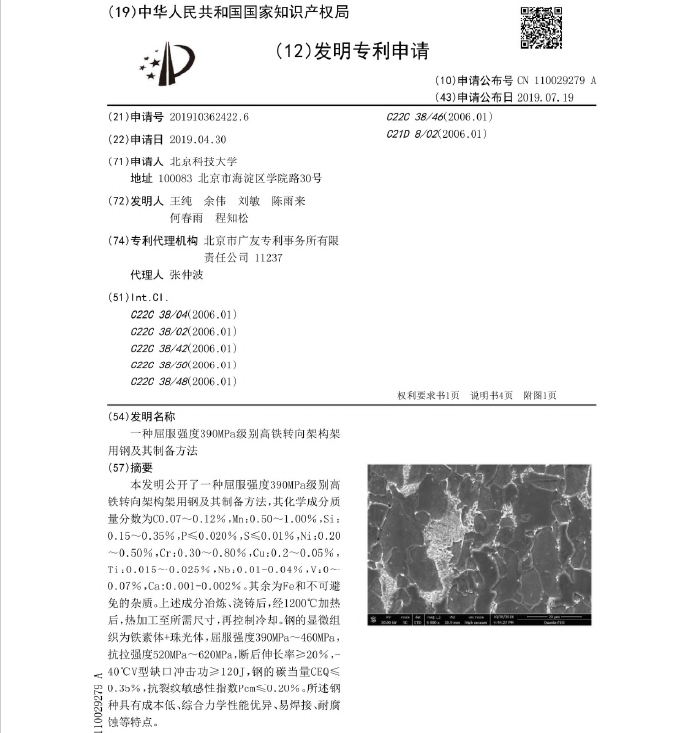

本发明公开了一种屈服强度390MPa级别高铁转向架构架用钢及其制备方法,其化学成分质量分数为C0.07~0.12%,Mn:0.50~1.00%,Si:0.15~0.35%,P≤0.020%,S≤0.01%,Ni:0.20~0.50%,Cr:0.30~0.80%,Cu:0.2~0.05%,Ti:0.015~0.025%,Nb:0.01‑0.04%,V:0~0.07%,Ca:0.001‑0.002%。其余为Fe和不可避免的杂质。上述成分冶炼、浇铸后,经1200℃加热后,热加工至所需尺寸,再控制冷却。钢的显微组织为铁素体+珠光体,屈服强度390MPa~460MPa,抗拉强度520MPa~620MPa,断后伸长率≥20%,‑40℃V型缺口冲击功≥120J,钢的碳当量CEQ≤0.35%,抗裂纹敏感性指数Pcm≤0.20%。所述钢种具有成本低、综合力学性能优异、易焊接、耐腐蚀等特点。

The present invention discloses a high-speed rail bogie frame steel with yield strength of 390 MPa and its preparation method. Its chemical composition mass fraction is C0.07 – 0.12 %, Mn : 0.50 – 1.00 %, Si : 0.15 – 0.35 %, P ≤ 0.020 %, S ≤ 0.01 %, Ni : 0.20 – 0.50 %, Cr : 0.30 – 0.80 %, Cu : 0.2 – 0.05 %, Ti : 0.015 – 0.025 %, Nb : 0.01 – 0.04 %, V : 0 – 0.07 %, Ca : 0.001 – 0.002 %. The rest are Fe and inevitable impurities. After smelting and casting, the above components are heated at 1200 °C to the required size, and then controlled cooling. The microstructure of the steel is ferrite + pearlite, with yield strength of 390 MPa – 460 MPa, tensile strength of 520 MPa – 620 MPa, elongation after fracture ≥ 20 %, − 40 °C V-notch impact energy ≥ 120 J, carbon equivalent CEQ ≤ 0.35 %, and crack sensitivity index Pcm ≤ 0.20 %. The steel has the characteristics of low cost, excellent comprehensive mechanical properties, easy welding and corrosion resistance.