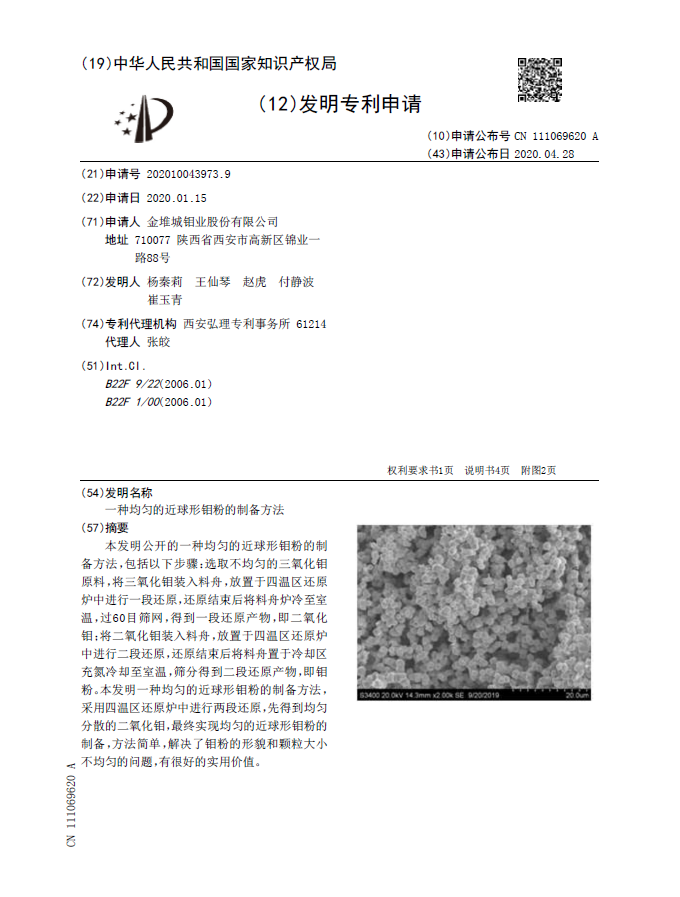

本发明公开的一种均匀的近球形钼粉的制备方法,包括以下步骤:选取不均匀的三氧化钼原料,将三氧化钼装入料舟,放置于四温区还原炉中进行一段还原,还原结束后将料舟炉冷至室温,过60目筛网,得到一段还原产物,即二氧化钼;将二氧化钼装入料舟,放置于四温区还原炉中进行二段还原,还原结束后将料舟置于冷却区充氮冷却至室温,筛分得到二段还原产物,即钼粉。本发明一种均匀的近球形钼粉的制备方法,采用四温区还原炉中进行两段还原,先得到均匀分散的二氧化钼,最终实现均匀的近球形钼粉的制备,方法简单,解决了钼粉的形貌和颗粒大小不均匀的问题,有很好的实用价值。

The method for preparing uniform and nearly spherical molybdenum powder disclosed in the present invention includes the following steps: selecting uneven molybdenum trioxide raw materials, loading the molybdenum trioxide into a boat, and placing it in a four-temperature zone reduction furnace for one-stage reduction. After the reduction, the material boat furnace is cooled to room temperature and passed through a 60-mesh screen to obtain a one-stage reduction product, namely molybdenum dioxide; the molybdenum dioxide is loaded into the material boat and placed in a four-temperature zone reduction furnace for two-stage reduction. After the end, the material boat is placed in the cooling zone, filled with nitrogen and cooled to room temperature, and sieved to obtain the second-stage reduction product, namely molybdenum powder. The present invention is a method for preparing uniform near-spherical molybdenum powder, which adopts two-stage reduction in a four-temperature zone reduction furnace, first obtains uniformly dispersed molybdenum dioxide, and finally realizes the preparation of uniform near-spherical molybdenum powder. The method is simple and solves the problem. To solve the problem of uneven morphology and particle size of molybdenum powder, it has very good practical value.