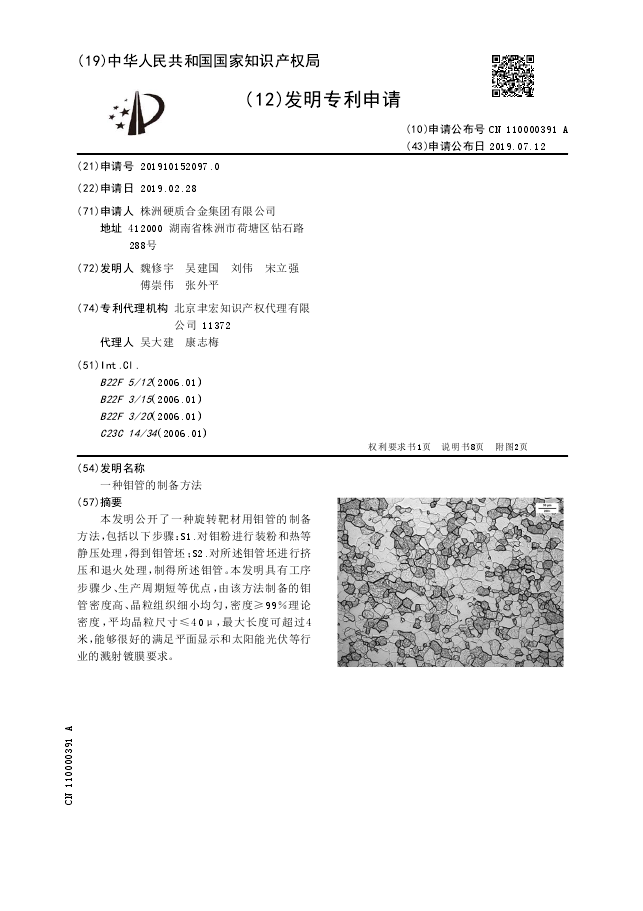

本发明公开了一种旋转靶材用钼管的制备方法,包括以下步骤:S1.对钼粉进行装粉和热等静压处理,得到钼管坯;S2对所述钼管坯进行挤压和退火处理,制得所述钼管。本发明具有工序步骤少、生产周期短等优点,由该方法制备的钼 管密度高、晶粒组织细小均匀,密度≥99%理论密度,平均晶粒尺寸≤40u,最大长度可超过4米,能够很好的满足平面显示和太阳能光伏等行业的溅射镀膜要求。

The invention discloses a method for preparing a molybdenum tube for a rotating target, comprising the following steps: S1. powder loading and hot isostatic pressing of molybdenum powder to obtain a molybdenum tube blank; S2 extruding the molybdenum tube blank And annealing treatment to obtain the molybdenum tube. The invention has the advantages of fewer process steps, short production cycle, etc. The molybdenum tube prepared by the method has high density, fine and uniform grain structure, density ≥99% of theoretical density, average grain size ≤40u, and maximum length of more than 4 meters. It can well meet the sputtering coating requirements of flat display and solar photovoltaic industries.